The quality of electronics in a product is linked to the chemicals and consumables that are used in the manufacturing process, particularly for printed circuit boards (PCBs) and other components. These also play an essential role in manufacturing products for the IT, telecommunications, flat panel display (FPD), computer and related industries.

The quality of electronics in a product is linked to the chemicals and consumables that are used in the manufacturing process, particularly for printed circuit boards (PCBs) and other components. These also play an essential role in manufacturing products for the IT, telecommunications, flat panel display (FPD), computer and related industries.

The growth of the electronics industry has a direct impact on the demand for the chemicals used by it. The market potential of the Indian chemical sector, therefore, seems to be enormous. At the same time, the quality, supply and price of electronic chemicals and materials affect the competitiveness of the electronics industry.

Latest technological offerings

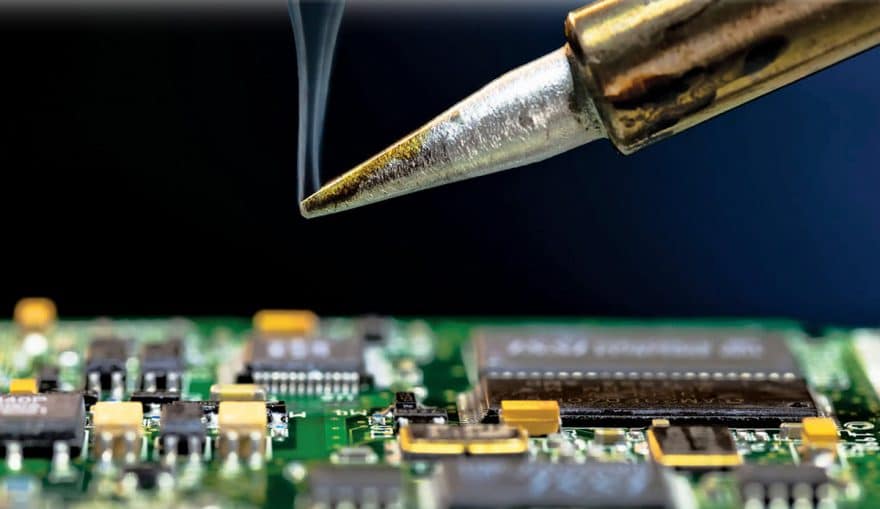

To cater to the increasingly challenging applications, today’s chemical soldering materials incorporate the most advanced technology. Soldering materials like lead-free solder pastes and tin-lead formulations are used for traditional and crossover manufacturing. Flux solutions are applied to dual-wave and lead-free processes, and cored solder wire and solid solder wire are some of the newer options available today to meet the demands of all kinds of applications.

Water-based (aqueous) chemicals are in high demand as they are environment friendly. Additionally, they have no flash point and do not foam. Therefore they can be applied in all spray-in-air equipment, such as inline or batch systems. These chemicals are also biodegradable and free of halogenated compounds. Silicon liquid flux is among the latest types of soldering flux available in the market. Listed below are some of the soldering materials that are in demand at present:

- Solder pastes suitable for miniaturised assemblies

- Low-temperature solder pastes

- Aqueous and lead-based consumables

- Adhesives that withstand preheating

- Soldering flux

Making the right choice

With such a wide range of chemicals and consumables with various features and benefits, it is important to make the right choice for a particular application. Ill-chosen consumables can have an adverse effect on running costs. Therefore, buyers must focus on factors like the working environment, the sensitivity of the surfaces of devices being handled, the method of application, etc, while buying consumables.

These chemicals can be hazardous. Moving the chemical from one place to another is a difficult affair. So buyers should go for quality, and choose the supplier with the better support system and a reputation for delivering on time. While the need is for safe, effective and easy-to-use materials, buyers should also look for chemicals that are RoHS compliant. Biodegradable variants are also a good option.

An optimal consumable is one that has the best quality and the longest life. Better quality consumables can decrease the post-weld work needed and cut down the downtime. Also, the longer the consumable lasts, the less time and money is spent on replacing it.

Hazardous chemicals and their implications

Source: Greenpeace |

| Some of the latest products available | |

| Product: NF372-TB soldering flux Kester NF372-TB is a zero-halogen, no-clean, low solids liquid flux designed to be used in wave and hand soldering processes. It can be used with both leaded and lead-free alloys. One of its best features is its wide processing window for thin boards and thick boards that require short or long dwell times and high preheat temperatures. Sustained activity within the flux allows for good barrel fill in challenging applications, such as reflowed copper OSP boards or with difficult-to-solder components. NF372-TB residues are minimal, clear and non-tacky, resulting in improved aesthetics. Contact: www.sumitron.com |

Product: F 640 series lead-free solder pastes The F 640 solder paste series is a state-of-art lead-free no-clean solder paste that promotes wetting and minimises soldering defects. The F 640 flux system is specifically optimised for Sn/Ag/Cu alloy soldering. Extensive testing at customer locations has proven this paste to be capable of defect-free performance in the production environment. The F 640 series exhibits minimal slump and has good print-after-wait performance. This formula works well on a variety of surfaces and finishes, while leaving behind a clear residue. Reflow can be accomplished in air or nitrogen. Contact: www.mectronics.in |

| Product: NP545 solder paste Kester NP545 is a zero-halogen, lead-free no-clean solder paste formula designed for consistency and repeatability. It is extremely stable and has an unrefrigerated shelf life of 12 months with no print or solderability degradation. NP545 consistently delivers paste transfer efficiencies of 0.55 to 0.5AR. The paste is also fully capable of printing and reflowing 01005 components, even in air reflow, with minimal graphing behaviour. NP545 is classified as ROL0 as per IPC J-STD-004B. Contact: www.sumitron.com |

Product: F352 series solder pastes The solder pastes of the F352 series comprise a ready-to-use homogeneous mixture with low odour characteristics. These pastes are made up of metal powder, binders, solvents, fluxes and thixotropic agents. Its flux is optimised to increase the paste’s wetting capability, decrease the odour of the paste, avoid solder balls (on chip-resistors and capacitors), and to increase tack time and stencil life. Solder pastes of the F352 series do not contain any halogen activators. They leave a low, clean flux residue with low ionic contamination and very high SIR. These pastes are insensitive to temperature and humidity. Contact: www.mectronics.in |

| Product: HYDRON SC 300 cleaning agent HYDRON SC 300 is a water-based, single-phased cleaning agent for SMT stencils at room temperature. It reliably removes solder pastes and especially SMT adhesives in one single process, and does not leave any adhesive pigment residues. It is recommended for cleaning and rinsing, and it dries residue-free. Contact: www.zestron.com |

|