The electronics & electricals industry has evolved in recent years. The industry invests significantly in new product development to meet the evolving needs of consumers.

Use of plastics in the manufacture of electrical appliances is increasing. Factors such as reduction in appliance weight, aesthetics, and favorable characteristics of plastics are boosting the usage of plastics in consumer electronics products. Expansion of the electronics & electricals industry is expected to boost demand for plastics in the near future. The demand for electronics, especially mobile phones and laptops, has been rising over the past couple of years. The demand is impacted by several factors such as availability of products and their trends, product development, per capita expenditure, disposable income, economic factors, etc.

Overall, the consumption of electronics is likely to be lower than their production. This trend is particularly pronounced in the case of mobile phones. A larger number of mobile phone manufacturers provide consumers with a wide variety of cell phones with a number of features. The production of laptops, notebooks, and desktops is dependent on the final use of the product such as gaming, business, or home office. Electronics used for entertainment, such as DVD players, video games, and MP3 players, are limited in number as compared to TVs, laptops, and mobile phones. However, they all utilize plastics in the production of their body-casing (enclosure).

Several countries do not have an established waste collection and sorting system for solid waste. For instance, just 10% of the total waste produced in Africa is channeled into the collection system. The remaining 90% lies unaccounted for and usually ends up in oceans and river streams. Furthermore, more than 8 million tons of plastic waste is estimated to end up in oceans. Collection and sorting of plastic waste is the first and crucial step in plastic recycling. Manufacturers of plastic products usually add several additives, pigments, modifiers, and fillers to induce properties such as high density, elasticity, rigidity, and color in products. However, these fillers, additives, and pigments create problems while recycling and ultimately result in poor quality of recycled plastics. Most plastics are non-biodegradable and remain in the environment for decades. Thus, various regulatory legislations have been imposed on the manufacture of plastics as well as their usage in different end-user industries in order to regulate production of plastics and plastic waste. Prices of oil and gas directly affect the cost of plastic manufacturing. Volatility in prices of oil and gas affects the raw material cost of virgin plastic production. For instance, decline in oil and gas prices can result in substantial decrease in prices of virgin polymers. As a result, demand for recycled plastics decreases, since prices of virgin plastics are low. However, volatility in prices of virgin plastics creates fluctuations in demand for recycled plastics. Thus, in terms of expansion potential, the plastics market for consumer electronics is estimated be adversely impacted by the above mentioned factors over the forecast period.

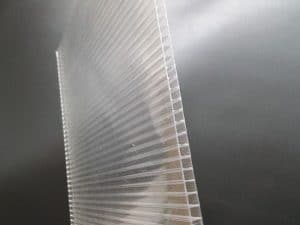

Based on product, the plastics market for consumer electronics can be segmented into polycarbonate (PC), acrylonitrile butadiene styrene (ABS), styrene-acrylonitrile resin (SAN), acrylonitrile styrene acrylester (ASA), polystyrene (PS), poly-(methyl methacrylate) (PMMA), and others (including styrene ethylene butadiene styrene (SEBS), polyphenylene ether (PPE), polyphenylene oxide (PPO), polyamide (PA), and plastic blends).

In terms of application, the plastics market for consumer electronics market can be divided into computers & accessories, cell phones, television sets, and sound systems (VCRs, CD players, DVD systems, etc.).

Asia Pacific is projected to be a lucrative region of the plastics market for consumer electronics as presence of numerous manufacturing facilities for electronic products in the region has elevated the demand for plastics in Asia Pacific. The region is a hub for the electrical & electronics industry in terms of production as well as consumption of electronic products.

In terms of demand, North America is anticipated to offer considerable opportunities to the plastics market for consumer electronics due to the presence of numerous plastic manufacturing facilities in the region. Furthermore, R&D required for selection, processing, and application of plastics in electronics is prominent in the region.

Europe currently holds a significant share of the plastics market for consumer electronics. However, increase in production costs and raw material prices are anticipated to hamper the plastics market for consumer electronics market in the region. Several economies (excluding Mexico) in Latin America are not performing well and have registered negative year-on-year growth. Therefore, the entire industrial sector, including manufacturing, in the region is anticipated to remain sluggish. Mexico, on the contrary, is an attractive country with respect to demand for plastics market in consumer electronics.

Key players operating in the plastics market for consumer electronics include LG Chem Ltd., DowDuPont, LyondellBasell, Trinseo, INEOS Group, SABIC, and ExxonMobil Corporation.