The interconnectivity of consumer electronics devices has led to complex test scenarios that require new and scalable test equipment.

The interconnectivity of consumer electronics devices has led to complex test scenarios that require new and scalable test equipment.

By Sneha Ambastha

The introduction of the Internet of Things (IoT) in consumer electronics has led to the production of more and more connected, smart and standards-compliant devices. This has brought about a lot of hardware and software design related challenges, increasing the testing requirements for these designs. Testing is required at every step of the product development cycle—while designing a wireless chipset or while integrating it into a product like a mobile phone. It is also required when integrating IoT technologies into the latest designs.

The role of testing

Testing plays a crucial role in the consumer electronics industry where there is a race on to make devices smaller, smarter and feature rich. Each product that goes out into the market needs to be tested for functionality, safety and performance. Tests in the consumer electronics industry are typically done at multiple stages of the design and development process. Mostly, these are component tests followed by integration tests and end-of-line production tests. Archan Mudwel, technical marketing engineer, National Instruments, says, “Component level testing can be either validation tests that are performed during the design phase or automated end-of-line production tests. Once the chipsets are designed, they need to be validated for their functionality, conformance to wireless standards as well as compliance with the EMI/EMC regulations. And finally, when the certified product is manufactured in production lines, automated tests are conducted to verify the functionality of each device before it enters the market.” So the testing requirements and test specifications differ in different phases. Madhukar Tripathi, senior manager-sales and marketing, Anritsu India Pvt Ltd, says, “Quality level testing takes place during the production process when each and every function of the product is tested as a combined unit or a package. However, in the R&D phase, the parts or the package of the products are tested.”

The functional validation tests include testing the core functionality of the device as well as the chipsets being used for communication over various wireless standards.

A note to buyers

Scalability of the product is very important with multiple technologies coming into use every other day. The test requirements of new products change with the introduction of new technologies. If the test instrument being used cannot be scaled to perform new tests, another test equipment will have to be purchased within a year. Thus, buyers should go for future-proof test systems scalable enough to add any new feature. They should look for test systems that can adapt to changes in requirements without much effort. “Previously, manufacturers used to buy multiple testing instruments and a lot of time went into integrating them together into a test system and automating the production tests,” says Mudwel. Selecting adaptable modular test platforms will minimise the amount of time spent on this tedious task.

Packaging adds to the challenge

Testing consumer electronics devices is quite different from the tests performed in the aerospace, defence, automotive, education or research fields. Today, consumer electronics demands small, cost-effective and low power consuming devices with wireless connectivity. This results in multiple challenges both at the R&D phase and during production. Improper testing of the products can lead to more repair and returns, just like what happened with the Samsung Galaxy Note 4. At the end of the day, such issues lead to the manufacturer losing its reputation, credibility and market share.

Components in close proximity: The small size of today’s consumer electronics products means the integration of more and more components in a small package. This creates a lot of issues like signal interferences, inductive or capacitive coupling, improper functioning of individual components, etc. Therefore, single products need to be tested multiple times, by using diverse test equipment for each component. The challenge is to identify the different types of issues that can arise and figure out the type of test equipment needed.

The small footprint of components and products: Traditional methods of testing consumer electronic devices involved connecting them with the test equipment via cables connected to ports, and communicating with them by sending electrical signals. But with these devices getting smaller, there is a limitation on connecting cables, especially when the process involves manual cabling. Mudwel says, “Such small devices need portless testing, which is done over some kind of a wireless standard, like WLAN, Bluetooth, Zigbee or mobile communication.”

Ensuring network security: IoT is taking us into a new world of connected devices, which is enabled by network infrastructure, the Internet and the World Wide Web. This increases the chances of network security breaches. To prevent this, the network stack, security layers and firewalls on these devices need to be tested, by simulating various use cases.

Cost of testing: The multiple testing methods using different test equipment to check the functionality of the product translates to higher testing and skilled labour costs. This calls for low-cost test equipment with more universal testing capabilities.

Deployed systems: Soon, most of the automation systems being deployed will no longer be connected to power sockets but be powered by batteries. Usually, wireless standards like Zigbee are preferred for low power consumption and the longevity of the battery. Mudwel says, “In the future, a lot the devices deployed will be battery powered. Some of them like CCTVs may rely on solar energy. Moreover, there may also be a requirement to charge systems wirelessly using inductive chargers.” These devices need to be tested for the life cycle as well as the endurance of their inductive charging capabilities.

Emerging new technologies

Five to 10 years back, most manufacturers used rack-and-stack box instruments for testing, which came with predefined test functionalities. But this trend has changed lately with modular testing equipment that have software defined functionality. Mudwel says, “Companies like Qualcomm have improved WLAN test speeds by 200x compared to traditional rack-and-stack instruments.”

Today, each box testing system has its own power supplies, displays, processors, memories, etc. These are all part of a single unit, with just the frontend circuitry exposed in the form of test cards. There might be multiple parts to such test equipment like an oscilloscope, a function generator or a digital multimeter, but its frontend will remain a constant. Basically, this kind of architecture is flexible and scalable, so that if testing needs change, the test equipment can be scaled up or modified.

Hardware testing tool suppliers move towards software testing: Ten years back, mobile phones were used only for making calls, but today they operate on a hardware platform with different functionalities defined through the software. Testing equipment too, now have the capability to change at the same rate at which the new devices are being launched. It is just the software that is changed in order to achieve new testing capabilities.

High speed production tests: There have been recent advances in high speed automated production tests, as a result of which the coverage of test cases as well as the speed of testing have improved considerably. There are a lot of robotic arms being used which operate at higher precision levels than the human arm, and can be used for assembling components on a printed circuit board (PCB). Visual feedback is also provided by cameras that inspect the placement of components, the quality of soldering, etc. There are switch modules and test management software that allow the same set of instruments to be used for parallel testing.

A few new products available in the market

All-in-one virtual bench

All-in-one virtual bench

The 8054 is an all-in-one virtual bench from National Instruments with an ability to combine the protocol analysis with a 4-channel mixed signal oscilloscope of bandwidth 500MHz, 5V TTL bi-directional digital lines with isolated 0-25V/0-1A and 0-6V/0-3A configurations, a programmable DC supply, a 14-bit arbitrary waveform generator with an update rate of 200MS/s and a 5½ -digit digital multimeter with resistance, continuity and both AC and DC current and voltage measurements. Over a standard Wi-Fi connection, this can be connected to an iPad or a PC wirelessly or over a wired network using a wired USB or Ethernet. For automated testing, it can be connected to LabView or can be plugged to be used with an interactive panel for benchtop testing/measurement.

Smart near-field communication tester

MP500 TCL3 is a high performance analyser or generator from Micropross. It is used for testing the characteristics of wireless chargers, contactless smart cards, smart readers and near field communication (NFC) devices. It has been specifically built for the laboratory environment and offers advanced signal generation features for flexibility. It supports standards like NFC Forum, EMVCo, ISO 14443 A/B, ISO 15693, FeliCa, MIFARE and Innovatron. MP500 TCL3 also supports very high bit rate (VHBR) of signal exchange in both amplitude-shift keying (ASK) and phase-shift keying (PSK) modes.

MP500 TCL3 is a high performance analyser or generator from Micropross. It is used for testing the characteristics of wireless chargers, contactless smart cards, smart readers and near field communication (NFC) devices. It has been specifically built for the laboratory environment and offers advanced signal generation features for flexibility. It supports standards like NFC Forum, EMVCo, ISO 14443 A/B, ISO 15693, FeliCa, MIFARE and Innovatron. MP500 TCL3 also supports very high bit rate (VHBR) of signal exchange in both amplitude-shift keying (ASK) and phase-shift keying (PSK) modes.

Ultra-portable spectrum analyser

Anritsu’s MS2760A is an ultra-portable spectrum analyser and is also called the Spectrum Master. Based on the shockLine non-linear transmission line (NLTL) technology, it is a pocket-sized product with good performance. Available at a low cost, it offers good sweep speed, dynamic range and amplitude accuracy. Its size allows it to be connected to almost any device under test (DUT). This handheld device allows continuous coverage from 9kHz to 11GHz. It is a USB powered device and can be used on the manufacturing floor, in labs and in the field; it can be controlled using a tablet, a laptop or even a Windows PC.

Anritsu’s MS2760A is an ultra-portable spectrum analyser and is also called the Spectrum Master. Based on the shockLine non-linear transmission line (NLTL) technology, it is a pocket-sized product with good performance. Available at a low cost, it offers good sweep speed, dynamic range and amplitude accuracy. Its size allows it to be connected to almost any device under test (DUT). This handheld device allows continuous coverage from 9kHz to 11GHz. It is a USB powered device and can be used on the manufacturing floor, in labs and in the field; it can be controlled using a tablet, a laptop or even a Windows PC.

NFC testing in manufacturing environment

MP500 PT1-NFC from Micropross is a single-box test solution for performing NFC tests and measurements in a manufacturing environment. It supports protocols like ISO 14443 A/B, ISO 15693, FeliCa and MIFARE along with card mode and reader/writer mode testing. It comes with a high-performance analogue measurement channel for performing qualitative measurements without sacrificing on test times. Though optimised for functional tests, the MP500 PT1-NFC also offers advanced signal generation features for defining wave shape parameters in both reader/writer and card emulation modes. In addition, its innovative triple antenna reduces the need for operator interaction by combining the functionality of an NFC reference listener (EMVCo PICC), an NFC reference poller (EMVCo PCD) and a resonant frequency antenna.

MP500 PT1-NFC from Micropross is a single-box test solution for performing NFC tests and measurements in a manufacturing environment. It supports protocols like ISO 14443 A/B, ISO 15693, FeliCa and MIFARE along with card mode and reader/writer mode testing. It comes with a high-performance analogue measurement channel for performing qualitative measurements without sacrificing on test times. Though optimised for functional tests, the MP500 PT1-NFC also offers advanced signal generation features for defining wave shape parameters in both reader/writer and card emulation modes. In addition, its innovative triple antenna reduces the need for operator interaction by combining the functionality of an NFC reference listener (EMVCo PICC), an NFC reference poller (EMVCo PCD) and a resonant frequency antenna.

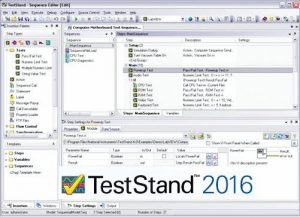

Ready-to-run test management software

TestStand 2016 is ready-to-run test management software from National Instruments that can help develop an automated validation and testing system faster. It can be used to develop test sequences for the integration of code modules, to execute tests and to log the test results automatically. The code written in TestStand can be integrated with the source code control, requirements management, and data management systems. TestStand has built-in options to test multiple devices in parallel, and also to run multiple tests on the same device simultaneously, allowing you to greatly increase test throughput while minimising the cost of additional test equipment. Sequences also specify execution flow, reporting, database logging, and connectivity to other enterprise systems. TestStand can automatically generate reports for each test in a variety of industry standard formats such as ATML, XML, HTML and text, as well as log these test results to your enterprise databases for future analysis. Finally, you can deploy test systems to production with easy-to-use operator interfaces.

TestStand 2016 is ready-to-run test management software from National Instruments that can help develop an automated validation and testing system faster. It can be used to develop test sequences for the integration of code modules, to execute tests and to log the test results automatically. The code written in TestStand can be integrated with the source code control, requirements management, and data management systems. TestStand has built-in options to test multiple devices in parallel, and also to run multiple tests on the same device simultaneously, allowing you to greatly increase test throughput while minimising the cost of additional test equipment. Sequences also specify execution flow, reporting, database logging, and connectivity to other enterprise systems. TestStand can automatically generate reports for each test in a variety of industry standard formats such as ATML, XML, HTML and text, as well as log these test results to your enterprise databases for future analysis. Finally, you can deploy test systems to production with easy-to-use operator interfaces.

Low cost vector network analyser

TTR500 is a series of two-port vector network analysers (VNA) from Tektronix available at a rate that the company claims is 40 per cent lower in price compared to the other competitive alternatives. Operating on a frequency range of 100kHz to 6GHz it delivers better RF performance on a dynamic range and comes with a built-in Bias Tee. The device has about six RF receivers and two RF sources that allow it to integrate the RF capabilities into application specific integrated circuits (ASICs) for high reliability. It draws about 13W of power and supports low energy consumption. It does not have a noisy fan either.

TTR500 is a series of two-port vector network analysers (VNA) from Tektronix available at a rate that the company claims is 40 per cent lower in price compared to the other competitive alternatives. Operating on a frequency range of 100kHz to 6GHz it delivers better RF performance on a dynamic range and comes with a built-in Bias Tee. The device has about six RF receivers and two RF sources that allow it to integrate the RF capabilities into application specific integrated circuits (ASICs) for high reliability. It draws about 13W of power and supports low energy consumption. It does not have a noisy fan either.

Wireless connectivity testing for WLAN

MT8862A from Anritsu is a wireless connectivity test solution for measuring the characteristics of devices working on WLAN IEEE802.11a/b/g/n/ac within the band range of 2.4GHz to 5GHz. It supports Rx sensitivity measurement along with the calculation of the packet error rate (PER). It allows real-time measurement of various data rates. It can be connected to an external PC with the help of an Ethernet cable for instant access and IP data exchange. It’s built-in frame capture logging feature allows troubleshooting of the connection problems.

MT8862A from Anritsu is a wireless connectivity test solution for measuring the characteristics of devices working on WLAN IEEE802.11a/b/g/n/ac within the band range of 2.4GHz to 5GHz. It supports Rx sensitivity measurement along with the calculation of the packet error rate (PER). It allows real-time measurement of various data rates. It can be connected to an external PC with the help of an Ethernet cable for instant access and IP data exchange. It’s built-in frame capture logging feature allows troubleshooting of the connection problems.

Low power source measurement unit

National Instruments’ PXIe 4135 is a source measurement unit (SMU) or a programmable DC power supply with very low voltage. It sources up to 20W DC power and features a four quadrant operation along with low current measurement range of 10nA with triaxial connectivity. This module works on an analogue-to-digital converter technology and can perform high precision measurements at a speed of up to 18MS/s with a current resolution of 10fA. This is suitable for testing the consumer electronics devices that work on low power and on silicon fibre based devices that work on minimal current and voltages. This instrument has a hardware timer with a high speed sequence engine that can synchronise acquisitions between multiple SMUs.

National Instruments’ PXIe 4135 is a source measurement unit (SMU) or a programmable DC power supply with very low voltage. It sources up to 20W DC power and features a four quadrant operation along with low current measurement range of 10nA with triaxial connectivity. This module works on an analogue-to-digital converter technology and can perform high precision measurements at a speed of up to 18MS/s with a current resolution of 10fA. This is suitable for testing the consumer electronics devices that work on low power and on silicon fibre based devices that work on minimal current and voltages. This instrument has a hardware timer with a high speed sequence engine that can synchronise acquisitions between multiple SMUs.

Universal wireless test set

MT8870A is a universal wireless test set from Anritsu capable of testing high volume smartphones, tablets and wireless modules. It supports various wireless connectivity applications like WLAN, Bluetooth, cellular, etc. It has a built-in audio analyser/generator and supports measurement of multiple wireless standards like W-CDMA/HSPA, GSM/EDGE, LTE/LTE-Advanced, TD-SCDMA, CDAM2000/1xEV-DO, WLAN 802.11b/g/a/n/p/ac (Wave 2), Bluetooth v5.0, ZigBee, Z-Wave, FM/RDS, GPS/Galileo/GLONASS/BeiDou, DVB-H and ISDB-T/ISDB-Tmm) simultaneously. Its frequency ranges from 10MHz to 6GHz. Its recently updated software ensures a simple and fast test environment to measure Bluetooth 2LE, basic rates, enhanced data rates (EDR), Bluetooth audio power, modulation accuracy, frequency, and Rx sensitivity parameters in order to ensure the standards-compliance of the products.

MT8870A is a universal wireless test set from Anritsu capable of testing high volume smartphones, tablets and wireless modules. It supports various wireless connectivity applications like WLAN, Bluetooth, cellular, etc. It has a built-in audio analyser/generator and supports measurement of multiple wireless standards like W-CDMA/HSPA, GSM/EDGE, LTE/LTE-Advanced, TD-SCDMA, CDAM2000/1xEV-DO, WLAN 802.11b/g/a/n/p/ac (Wave 2), Bluetooth v5.0, ZigBee, Z-Wave, FM/RDS, GPS/Galileo/GLONASS/BeiDou, DVB-H and ISDB-T/ISDB-Tmm) simultaneously. Its frequency ranges from 10MHz to 6GHz. Its recently updated software ensures a simple and fast test environment to measure Bluetooth 2LE, basic rates, enhanced data rates (EDR), Bluetooth audio power, modulation accuracy, frequency, and Rx sensitivity parameters in order to ensure the standards-compliance of the products.

What lies ahead?

With more and more cyber physical systems being brought into use (where cyber refers to connectivity and physical systems are those that can sense the environment around), consumer electronics devices will become capable of taking autonomous decisions rather than function on the basis of centralised processing and decision making. The challenge associated with using these small, autonomous devices lies in testing their network security, battery life and connectivity. We shall also see a rise in technologies like inductive wireless charging of batteries and, hence, the systems needed to test the same.