Any good industrial battery must offer reliability, economy, durability and safety. Let’s take a look at some batteries that come with all these benefits.

Any good industrial battery must offer reliability, economy, durability and safety. Let’s take a look at some batteries that come with all these benefits.

By Shruti Mishra

For heavy duty applications, industries need robust and rugged batteries that can support multiple functions in one go. Industrial batteries are mainly used for operating power, backup power and energy regulations. These hardworking heroes are responsible for the smooth functioning and uninterrupted working of massive industries.

With the boom in technology, growing consumer demand and the rapid metamorphosis of startups into giant companies, the consumption of industrial batteries has increased manifold. According to research conducted by MarketsandMarkets, the worldwide industrial batteries market is projected to reach US$ 10.84 billion by 2021, at a CAGR of 6.5 per cent between 2016 and 2021. India is also witnessing growth in the sale of these batteries as major sectors like telecom, railways, power, etc, are powered by batteries.

Types of batteries used in industries

For large industrial or sub-station applications, mainly three types of batteries are used:

Valve-regulated lead acid (VRLA) batteries: These are a type of rechargeable lead-acid batteries that are typically used in plants, where maintenance and space are not really an issue.

In VRLA batteries, lead plates react with acid and water in the process of storing electricity and heat up the battery. A valve releases any excess pressure that may build up if the battery is failing.

Limitations: The VRLA battery’s design is such that it will wear out even in ideal conditions. Such batteries cannot withstand very high temperatures and overcharging.

Sealed maintenance-free (SMF) batteries: In SMF batteries, the electrolyte used is in the form of gel, which fills the cavity of the plates. As the name suggests, these batteries are sealed completely and, therefore, eliminate the hassles associated with checking the specific gravity and adding distilled water or acid.

Limitations: SMF batteries are sensitive to temperature and have a low service life.

Nickel cadmium (Ni-cd) batteries: These are the most expensive of the batteries discussed. Nickel and cadmium are used in varying compositions depending on the size of the battery. Ni-Cd batteries need moderate maintenance as they consume very little water.

Limitations: The presence of cadmium, a highly toxic heavy metal, can cause substantial pollution when disposed of in landfills or when incinerated.

The technologies involved

There is no single type of battery that is suitable for all applications. Also, there are different battery manufacturing processes, based on different technologies. Let’s have a look at some of the major technologies used in industrial batteries.

Gel technology: Batteries based on gel technology are extremely robust and versatile. These are valve regulated lead acid batteries with a gel-based electrolyte made of sulphuric acid, water and lead plates.

The upside: The presence of gel electrolyte reduces the risk of leakage and, for that reason, these batteries can be placed anywhere or in any position. These batteries are more suitable for deep cycle applications.

The downside: Gel batteries have low heat dissipation capabilities and manufacturers tend to offer shorter warranty periods.

Absorbed glass mat (AGM) technology: In batteries with AGM technology, a thin ultra-fine fibre glass mat is sandwiched between the plates that are saturated with battery acid to about 95 per cent. The mat is tightly packed between plates and then welded or soldered in place. AGM batteries are mostly used for light cycling and engine-starting applications.

The upside: As mats and plates are encased fairly tightly, AGM batteries are almost immune to vibrations. These batteries charge five times faster and have a better cycle life than flooded systems.

The downside: These batteries do not tolerate heat and overcharging the latter burns the lead and electrolyte, leading to premature failure.

Tubular-plate technology: In such batteries, chemical compounds are sealed in tubular plates known as gauntlets that are placed on the battery plate’s surface. The biggest advantage of the tubular structure is that it dramatically decreases the corrosion or the shedding of the plates and prolongs battery life.

The upside: Tubular batteries require minimum maintenance. They are ideal for high-end gadgets and applications, for which general chemical cells are not suitable.

The downside: These batteries do not have an efficient heat transfer mechanism.

A few products available in the market

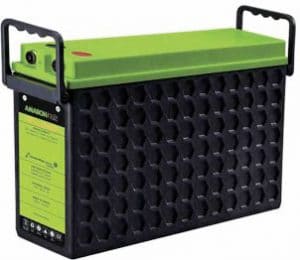

Model: Amaron Sleek, Manufacturer: Amara Raja

Amara Raja’s Amaron Sleek is a high performance battery designed to meet the demands of a wide range of industrial applications. The Amaron Sleek range is modular in structure and is capable of accommodating a wide spectrum of capacities depending on the application. Major application areas include telecommunications, power utilities, railways, defence and other heavy industries. The designed float life of this battery is more than 12 years, which is classified as ‘long life’ as per Eurobat Classification.

Key features

Key features

- Self-discharge: Less than 1 per cent per week

- Operating conditions: -40°C to +60°C

- Design float life: 12+ years at 27°C

- Design cycle life: 1800+ at 20 per cent DOD, 900+ at 50 per cent DOD, 500+ at 80 per cent DOD

- Recombination efficiency: >99 per cent

Contact: www.amararaja.co.in

Model: OB 100-12, Manufacturer: Okaya Battery

The OB 100-12 is a maintenance-free battery made in a modern and eco-friendly manufacturing facility. The lead calcium-tin grid offers extended life and enables the battery to operate in a wide temperature range. Its leak-proof construction gives the battery a long service life.

Key features

Key features

- Capacity: 100Ah

- Dimensions (L x W x H): 360mm x 172mm x 196mm

- Net weight: 30.5kg

- Nominal voltage: 12V

- Rated capacity: 100Ah

Contact: www.okayapower.com

Model: Cellyte UPS series (AGM), Manufacturer: SEC Battery Co.

With a large plate surface area and efficient active material processing, SEC’s Cellyte UPS batteries are designed for high power applications. According to company sources, these batteries are the first to use a CatVent (TM) catalyst in the cell headspace, which provides longer battery life and lower running costs. Plus, the addition of the catalyst delays cell dry-out and reduces cell heating, which significantly lessens the risk of thermal runaway or accidental fires.

Key features

Key features

- Design life: >10 years

- Operating voltage: 6V and 12V

- Capacity: 24-150Ah

- Warranty: 2 years

- Abuse-resistant

- Reliable under temperature fluctuations

Contact: www.secbattery.com

Model: JCSMFVRLA 12-150, Manufacturer: JC Batteries

Based on absorbed glass mat technology (AGM), JC’s SMF VRLA batteries are eco-friendly and used for multiple industrial applications like UPS systems, telecommunication equipment, solar power systems, etc. These batteries have excellent charge retention and recovering capabilities. They are tested as per JIS C 8702 standards and offer long service and shelf life.

Key features

Key features

- Capacity: 150Ah

- Voltage: 12V

- Weight: 46kg

- Overall dimensions (L x W x H): 485mm x 170mm x 253mm

- Low self-discharge

- Explosion-resistant

Contact: www.jcbattery.in

Model: SBT 1800, Manufacturer: Su-Kam Power Systems Ltd

Tubular-plate technology enables these batteries to deliver larger amounts of consistent, reliable power. They are engineered to deliver increased power and efficiency while maximising battery life. The tubular-plate batteries perform better on heavy-duty applications. Even the maintenance required with these batteries is relatively less. The batteries withstand long and frequent power cuts.

Key features

Key features

- Capacity at 27°C: 180Ah

- Weight: 65kg

- Dimensions (L x W x H): 503mm x 193mm x 412mm

- Charging current: 18 amp

- Warranty: 48 months

- Extra thick gauntlets suitable for Indian climatic conditions

- Aesthetically designed, with small footprint

Contact: www.su-kam.com