High power LEDs (HPL) are being adopted across the lighting industry because of their ability to achieve higher luminous flux at a reduced cost. Let’s have a look at some of the recent technological advances and launches in this category.

High power LEDs (HPL) are being adopted across the lighting industry because of their ability to achieve higher luminous flux at a reduced cost. Let’s have a look at some of the recent technological advances and launches in this category.

By Shruti Mishra

High power LEDs (HPLs) offer unparalleled lighting performance by consuming less power than standard LEDs.

Generally, LEDs with at least 1 watt capacity can be termed as high power or high brightness LEDs. Standard LEDs are good for home and light commercial applications but there are some industries that need more powerful and durable lighting systems. Due to their high luminosity and high efficiency, HPLs are a good option for applications that require high intensity light.

Today, a lot of industries like automobiles, healthcare and advertising are increasingly integrating HPLs while developing and manufacturing new products. One area that has directly benefited from the arrival of HPLs is horticulture. This sector uses these LEDs as an artificial source of light to help in the cultivation of certain plants. Unlike the sodium or fluorescent lights that were used earlier, HPLs are flexible and deliver specific wavelength combinations and lighting strategies that lead to faster plant growth.

Benefits of high power LEDs

- Enhanced efficiency

- Reduced cost

- Durability

- Better quality of light

Technological improvements

Let’s have a look at some crucial technological advances that have made HPLs more desirable as a light source.

- Silicon carbide substrate: The arrival of this technology has not only paved the way for the next generation of LED lighting but also reduced the total system cost by up to 40 per cent in most lighting applications. Popularly known as SiC technology, it is considered as one of the most effective commercial options to the conventional indium gallium nitride (InGaN) and sapphire substrate, with the potential to double the luminosity of single LEDs.

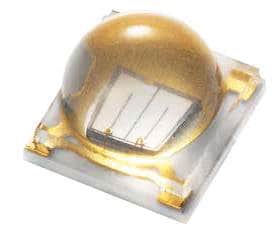

- Advances in lens curvature: To achieve better light extraction efficiency in an LED, it is very important to improve the cup angle and lens curvature. Improper lens curvature or the wrong packaging of the LED chip can reduce power output by more than 10 per cent. Therefore, many manufacturers these days are designing a low viewing angle and high extraction package based on the total internal reflection of the lens. Such lenses are capable of producing a light output with a low dispersion angle and high brightness.

A checklist to go through before buying HPLs

- LM80 certification: This is a standard approved by the Illuminating Engineering Society of North America (IESNA) that measures the lumen depreciation of LEDs. This rating gives information about how HPLs perform over a period of time under certain conditions. This rating requires a minimum testing period of 6,000 hours, with 10,000 hours being the preferred option.

- Power factor: This is defined as the ratio of real power (used power) and apparent power (wasted power). In case of HPLs, this ratio should not be less than 0.9. A power factor lower than this implies a higher loss of power in the form of heat.

- Lumens: While shopping for LEDs, many look at the wattage to determine brightness. But in reality, watts have nothing to do with brightness. Wattage only indicates how much energy a LED draws. To find out how bright the HPL will be, one must look at its lumen value before making a purchase.

Application areas

- Automotive industry: Taillights and headlights, turn signals, dashboard backlighting, licence plate illumination and signal lighting

- Healthcare industry: Surgical lighting, emergency lighting, sensor systems, diagnostic equipment, digital scales and monitors

- Public lighting applications: LED traffic lights, LED street lights

- Advertising industry: Exit lighting, signs boards and billboards

- Agriculture and livestock farming: Lighting of poultry barns, indoor farming light bars, horticultural LED grow lights and cold storage lighting

Some recently launched products

Model: XHP70.2, Manufacturer: Cree, Launched in: March 2017

The XLamp XHP70.2 LED is the second generation of the high output, extreme high power LED, which delivers up to 9 per cent more lumens and 18 per cent higher lumens-per-watt (LPW) than the first generation XHP70 LED. Built on Cree’s latest high power LED technology, the company claims that the XHP70.2 LED provides up to 58 per cent higher lumen density than the closest competing LEDs of the same size, enabling smaller luminaires and better optical control for high-lumen lighting applications. Its good lumen density and longer lifetime at higher operating temperatures also enables new and innovative lighting designs.

Key features

Key features

- Viewing angle: 125°

- Product options: 6V, 12V

- Maximum drive current: 4.8A for 6V, 2.4A for 12V

- Maximum power: 29W

- Maximum light output: 4292lm

- Maximum efficacy at binning conditions: 181lm/W

- Reflow solderable: Yes, JEDEC J-STD-020C-compatible

- Thermal resistance: 0.9°C/W

- RoHS compliant: Yes

- REACH compliant: Yes

Contact: www.cree.com

Model: LUXEON 5050, Manufacturer: Lumileds, Launched in: October 2016

Lumileds’ LUXEON 5050 high-power LEDs deliver high luminance from a single, multi-die package to enable cost-effective, single optic and directional fixture designs. LUXEON 5050 LEDs use an industry standard 5050 surface mount package with an extremely small, 4.6mm light emitting surface (LES). The LEDs come in 70CRI, 80CRI and 90CRI with a wide range of colour temperatures. Hot-colour targeting ensures that these LEDs are within their colour target at application conditions of 85°C.

Application areas: Downlights, high and low bay lights, lamps, outdoor lights and spotlights

Key features

Key features

- Forward voltage: 23.5V to 26.5V

- DC forward current: 240mA

- Peak pulsed forward current: 300mA

- LED junction temperature (DC and pulse): 125°C

- Operating temperature: 105°C

- LED storage temperature: -40°C to 105°C

Contact: www.lumileds.com

Model: VLMU3510-365-130, Manufacturer: Vishay Semiconductors, Launched in: May 2016

Vishay Semiconductors has launched a new device in its VLMU35xx series of ceramic-based, high-power UV LEDs with silicone lenses. Designed to provide a reliable, energy-saving replacement for mercury lamps, the VLMU3510-365-130 silicone lens enables lifetimes of up to 25,000 hours, company sources claim, compared to the typical mercury lamp lifetime of 10,000 hours. Available in a compact surface-mount package, the environment friendly UV LED is free of heavy metals and provides reliability through its shock resistance and immunity to degradation from frequent on/off switching.

Application areas: Suitable for medical, industrial and printing applications

Application areas: Suitable for medical, industrial and printing applications

Key features

- Wavelength/colour temperature: 367nm

- Luminous flux/radiant flux: 690mW

- Forward current: 500mA

- Forward voltage: 4V

- Power rating: 3W

- Dimensions (L x W x H): 3.45mm x 3.45mm x 2.1mm

- Maximum operating temperature: + 85ºC

- Viewing angle: 130°

Contact: www.vishay.com

Model: PLW7070GA, Manufacturer: Plessey, Launched in: October 2016

The PLW7070GA is a high power LED designed with multiple junctions integrated in a single chip. It provides a 30 per cent increase in light output when using any standard secondary optics. Based on GaN-on-Si die technology, the PLW7070GA helps in eliminating shadow effects and also provides optimised far-field imaging. The use of advanced thermal management helps the LED in maintaining luminous flux over the widest possible temperature range.

Application areas: Spotlights, floodlights, streetlights, high bays and portables

Application areas: Spotlights, floodlights, streetlights, high bays and portables

Key features

- Colour rendering index (CRI): 70 to 90

- Operating input current: 350mA to 3A

- Nominal flux: 680lm to 1040lm

- Nominal forward voltage: 11.8V

- Nominal forward current: 700mA

- Viewing angle: 120°

- Dimensions (L x W x H): 7.0mm x 7.0mm x 3.88mm

Contact: www.plesseysemiconductors.com