In a bid to provide more efficient and cost-effective lighting methods, LED companies opt for PCBs with good heat dissipating properties

In a bid to provide more efficient and cost-effective lighting methods, LED companies opt for PCBs with good heat dissipating properties

By Shruti Mishra

The progress of printed circuit board (PCB) technology has paved the way for the creation of innovative electronic products. One prime area that has directly benefited from this is the LED lighting industry.

Earlier, the traditional fibre glass (or ceramic based) PCBs were used extensively in the industrial sector. But, these days, for many companies in the LED industry, metal core PCBs (MCPCBs) are the new standard. The main reason for this switch is that traditional FR4 PCBs generate more heat, which has an adverse effect on the functioning of the LEDs.

So, before proceeding further, let’s first discuss why metal core PCBs are so popular and what are the advantages they offer.

Better heat dissipation: The most common metal used for MCPCBs is aluminium, which has an excellent ability to dissipate heat. This, and the presence of a thermally conductive dielectric layer, results in less failure of electronic components.

High temperature stability: In comparison with FR4 PCBs, MCPCBs are much more stable, which makes them more suitable for high temperature environments.

Improved durability: Compared to fibre glass and ceramic, aluminium is much stronger. This means there is less breakage in the case of MCPCBs, since aluminium can handle the stresses of the manufacturing process, as well as everyday handling, better—especially in impact-prone environments.

Cost-effective: Aluminium is available in abundance and, hence, mining and refining it is significantly cheaper than other metals. As a result, manufacturing aluminium PCBs is also inexpensive.

Lightweight: Despite being strong and durable, aluminium is very lightweight. It enhances resilience without additional weight, which makes shipping and handling of circuit boards and end products cheaper and easier.

Currently, aluminium and copper are the two metals used by metal core or MCPCB manufacturers. As we all know, copper is a better performer than aluminium in terms of its heat transferring and dissipation capabilities. But aluminium is relatively more popular and used widely across the PCB industry as the base/core material because it is the most economic option considering its thermal conductivity, rigidness and cost.

Why metal core PCBs are a wise choice for the LED industry

It is a known fact that wherever there is light, there is heat. So since LED lights also produce heat while in operation, their heat dissipation properties are very important for LED PCBs.

The efficient heat transfer properties of MCPCBs enhance the following capabilities of LEDs:

- Longer operating life: The improved heat transferring qualities of MCPCBs result in the vastly longer life span of LEDs. That is why the LED industry is quickly embracing aluminium PCBs as they can operate for much longer.

- Increased LED density: The high thermal conductivity of MCPCBs enables manufacturers to mount a greater number of LEDs onto them. This means that more LEDs can function simultaneously on a single board without exceeding the specified temperature tolerance.

| Copper-based PCBs | Aluminium-based PCBs |

| Excellent heat transfer and dissipation capabilities | Relatively lower heat transfer and dissipation capabilities |

| Heavier metal | Lighter metal |

| Expensive | Cheaper |

| Used in very few LED applications | Used extensively in almost all LED applications |

A few products available in the market

Model: JHD-BB-14013, Manufacturer: Shenzhen Jianhongda Technology Co. Ltd

This PCB is completely free from mercury or any hazardous material. It is very safe for any LED lighting application and can be fully recycled.

Key features

Key features

- Base material: Aluminium

- Number of layers: One

- Board thickness: 1mm, 1.2mm, 1.5mm, 2mm, 3mm

- Board dimensions: Diameter—30mm, 45mm, 50mm, 55mm, 60mm, 65mm (it can be customised)

- Copper layer: 28gms/57gms/85gms

- Solder mask: White, black, blue, red

- Silkscreen: Black

- Surface finish: LF HAL, HAL, OSP, gold immersion, silver plating

- Outline profile: CNC routing, V-cut

- Thermal conductivity: 1.0~20W/MK

- Voltage that they can withstand: AC 2000V, DC 1500V~4000V

Contact: www.ledlightpcb.com

Model: LED PCB, Manufacturer: XNJ PCB

These metal PCB boards have good thermal conductivity, electrical insulation and machining performance. They are manufactured to UL standards and comply with RoHS rules.

Key features

Key features

- Surface finishing: Lead-free HASL, immersion gold, golden finger, immersion tin, immersion silver, OSP, carbon oil, plated hard gold

- Layer: Single-sided, two-sided, multi-layer and special layer

- Max. PCB size: 1200mm x 646mm

- PCB thickness: 0.5mm – 6mm

- Copper thickness: 14gms, 28gms, 57gms, 85gms, 113gms, 170gms

- Hole diameter: 0.075mm

- Hole tolerance: -0.05mm~0.05mm

Contact: www.xnjpcb.com

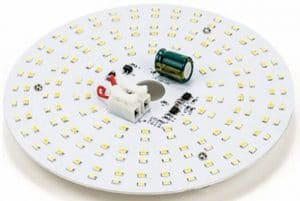

Model: Round LED panel PCB, Manufacturer: Jinghon Circuits

These round LED panel PCBs are used in a wide range of high-tech industries such as LEDs, telecommunications, game machines, industrial controls, power, automobile and high-end consumer electronics. They offer high heat dissipation, electromagnetic shielding, high mechanical strength and good processing performance.

Key features

Key features

- Product type: Aluminium-clad PCBs (single and double layer)

- Maximum panel size: 1170mm x 600mm (20” x 24”)

- Copper thickness: 14gms, 28gms, 57gms, 85gms and 113gms

- Dielectric thickness (to substrate): 0.05mm, 0.075mm, 0.1mm, 0.15mm, 0.2mm

- Substrate core thickness: 0.4mm, 0.6mm, 0.8mm, 1.0mm, 1.2mm, 1.5mm, 2mm, 3mm and 3.2mm

- Finished board thickness: 0.4mm – 4mm

- Thickness tolerance: +/-10 per cent

- Min. finished hole diameter: 0.25mm

- Max. working voltage: 2.5kV DC (0.075mm dielectric), 3.75kV DC (0.15mm dielectric)

- Surface finishing: HASL, HASL lead-free, immersion gold, flash gold, OSP

- Solder mask colour: White, black and other options available

- Reference standard: IPC-A-600G Class 2

Contact: www.jhcircuits.com

Model: POE-399, Manufacturer: Poe Precision Electronics Co. Ltd

Poe PCBs are the result of cutting-edge technology and high precision processes. Apart from LED lights, these are also used in communications, aerospace, defence, IT, medical equipment, precision test equipment and industrial control companies.

Key features

Key features

- Number of layers: One

- Material: Aluminium

- Thickness: 1.5mm

- Copper layer: 28gms

- Hole diameter: 0.2mm

- Minimum width/space: 0.1mm/0.1mm

- Testing points: 1000

- Solder mask: LPI white

- Silkscreen: Black

- Finish: HASL lead-free

Contact: www.poe-pcba.com

Model: Aluminium LED PCB with mirror reflector, Manufacturer: Shenzhen Kingtinly Electronic Co. Ltd

Surface mounted technology that is used in the manufacture of this PCB lowers the temperature to improve power capacity, thus ensuring a longer life. And the compact shape makes it stronger.

Key features

Key features

- Board material: Aluminium, copper, FR-4, CEM-3

- Type: Rigid circuit board

- Number of layers: 1 – 20

- Board thickness: 0.5mm – 4mm

- Copper layer: 14gms – 142gms

- Min. line width: 0.2mm

- Min. line spacing: 0.5mm

- Min. hole diameter: 2mm

- Solder mask colour: White, black, green, red

- Outline tolerance: +/- 0.1mm

- Surface finish: HASL, gold immersion, silver immersion, ENIG, ENEPIG

Contact: www.kitili.en.made-in-china.com