To expand the reach of LED lights, makers of LED modules are shifting their focus away from general lighting applications and towards untapped markets that have higher margins.

To expand the reach of LED lights, makers of LED modules are shifting their focus away from general lighting applications and towards untapped markets that have higher margins.

By Shruti Mishra

The LED module industry is undergoing massive tech innovations to make the use of LED lights common in areas where these are not so popular today.

An important feature of LED modules is that they help in controlling the heat-induced deterioration of lights, which ensures the product has a longer life span. Because of this property, they are well suited for robust industrial applications that demand long-lasting components with higher light output, thereby minimising the need for a large number of luminaires.

To make sure that the right kind of LED module is used in a particular industry, LED module makers are innovating based on the specific requirements of an application area or system architecture.

For instance, consumers can opt for LED modules with remote phosphor technology for industries that require uniform light, without any colour shift, from a large light-emitting surface area. Those looking to make their finished product more sleek can make use of LED modules with plug-and-play technology, which come with embedded driver ICs and reduce the need for attaching any components externally. And to fulfil the requirement of smart or connected lighting, LED modules with Bluetooth based wireless communication can be used—these help LED lights to be connected to any device.

The introduction of such technologies is not only making LED modules market-ready but also paving the way for LED lights to enter some brand new segments.

New emerging markets

Initially, the growth in the LED module sector came from general lighting applications. Being the most mainstream sector of the lighting industry, it is currently experiencing intense competition and price pressures due to the entry of a large number of players. Therefore, LED module manufacturers are looking for some new applications that can yield higher margins.

Industry players point out that fields like horticulture, automotive lighting and smart lighting are gradually becoming significant consumers of LED modules. With their high efficiency, low standby power losses, increased dielectric strength for extended temperature ranges and their design flexibility, LED modules are capable of meeting the specific requirements of these industries. What’s more, their enhanced thermal behaviour and safety features are making them better replacements for fluorescent lights in hard-core industrial applications.

The penetration of LED lights in the fields mentioned is extremely low at present, but the scope for good margins is much higher as compared to general lighting. LED module manufacturers are quite confident that targeting these new applications will not only help them to go up higher in the value chain, but will also lead to profitable results in the long run.

In addition, LED module manufacturers are also moving beyond visible light and diversifying into the infrared (IR) or ultraviolet (UV) parts of the light spectrum. The rapidly growing markets for UV curing lights and IR surveillance cameras are pushing up the sales of UV and IR LED modules to a great extent.

The current market state

In view of the intense demand for LED modules in various applications, Yole Development (a French multinational consulting and market research company) has highlighted certain factors in its report, titled ‘LED Lighting Module Technology, Industry & Market Trends’ (2017 edition). The report claims that the global LED lighting module market will deliver a 22.6 per cent CAGR from 2017 to 2022. According to the report, the LED lighting modules (including mid/high power modules, COB and flexible strips sold in the open market), represented a market size of US$ 4 billion in 2016, which is expected to reach US$ 13.8 billion in 2022.

The reason for this surge lies not only in the wide application areas of LED modules but also in an easier production process. LED modules have a faster product development cycle and are easy to integrate into the lighting architecture, which is helping LED manufacturers to earn quick profits.

Talking about India, LED bulbs are becoming part of the mainstream LED lighting industry due to government initiatives and increasing public awareness about the benefits of using LED lights. That is why the Indian LED industry is expected to grow at a CAGR of 26.6 per cent during 2017-2023, as per 6Wresearch, which is 4 per cent more than the global rate of growth indicated in the Yole report.

Associated components (including LED modules) will benefit from this growth, but few local LED module makers will be able to cash in on this massive opportunity properly and may end up sourcing from Chinese LED module makers and suppliers.

New products in the market

Model: QLE G1, Manufacturer: Tridonic

The QLE G1 ADV IND line of LED modules from Tridonic is designed for industrial lighting luminaires. This new range is ideal for ceiling luminaires and can be used in applications that require high lumen values and robustness. QLE is designed to provide homogeneity with 600mm x 600mm and 625mm x 625mm fittings.

Key features

Key features

-

Luminous flux range: 1,870lm to 4,070lm

-

High colour rendering index (CRI): Greater than 80

-

Colour temperatures: 3,000K, 4,000K, 5,000K and 6,500K

-

Operating time: 50,000 hours

-

Efficacy: Up to 163 lm/W

Contact: www.tridonic.com

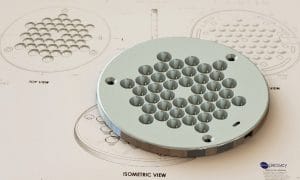

Model: Orion PLWS3000C series, Manufacturer: Plessey Semiconductors

The new Orion PLWS3000C series of LED modules provides an innovative approach to directional lighting applications, opening up new opportunities for industrial and architectural lighting design. The series also has a small heat-sink, resulting in a smaller and lighter luminaire. This will positively impact luminaire packaging and logistics

Key features

Key features

-

Module thickness: 5.6mm

-

Thermal resistance: 1°C/W

-

Beam angles: 60°, 25° or 15°

-

Forward current: 700mA

Contact: www.plesseysemiconductors.com

Model: 1500 AG series, Manufacturer: Keystone Technologies

The AlumaGroove LED module series has standalone systems that can be installed almost anywhere without the need for further heat sinking. Integrated thermal management means a cool operating temperature. The sleek AlumaGroove LED module can be installed 50 per cent faster than standard linear modules, company sources claim. It fits easily and securely into any new or existing light fixture.

Key features

Key features

-

Operating life: Greater than 50,000 hours at 105ºC

-

Forward voltage: 30V

-

Completely heat-sinked, no additional heat-sinking needed to extend lifetime

-

Made with UL recognised components

Contact: http://keystonetech.com