The LED lamp market will grow at 25 per cent annually to reach $25 billion in 2023. Hence LED light manufacturing is a profitable investment opportunity for entrepreneurs

Light-emitting diodes (LEDs) are semiconductor devices that emit visible light when electric current passes through them. Compared to conventional lighting systems, these are smaller, have a longer operating life and involve a lower cost of ownership. Available in a wide range of colours, LED light bulbs are more durable and offer comparable or better light quality than other types of lighting.

Residential LED lights, especially Energy Star rated products, consume at least 75 per cent less energy and last 25 times longer than incandescent lights. These also use significantly less power—a typical 84-watt fluorescent light can be replaced with a 36-watt LED to give the same level of light output.

The LED lamp market is projected to grow at 25 per cent annually to reach $25 billion in 2023. Hence LED light manufacturing is a profitable investment opportunity for entrepreneurs.

Full-scale LED light manufacturing requires setting up of a large-scale factory with a complex production process. However, it is possible for small-scale entrepreneurs to set up LED light assembly units as a small- or medium-scale manufacturing operation.

Process

LED-based lighting system cum LED lamp assembly consists of the following steps:

1. Procure/import milliwatt-rated LED chips, circuit and other mounting devices

2. Embed milliwatt-rated LED chips on the PCB board with the rectifier circuit, filter circuit, etc

3. Fit the PCB board with a holder cap and plastic modules fitted with Smokey reflector to form a compact unit

4. Test the assembled LED lighting system and package

Raw materials

For assembly of LED-based lighting systems up to 10W you may require:

1. LED chips

2. Rectifier circuit with filter

3. Heat-sink devices

4. Metallic cap holder

5. Plastic body

6. Reflector plastic glass

7. Connecting wire

8. Soldering flux

9. Miscellaneous items

10. Packaging material

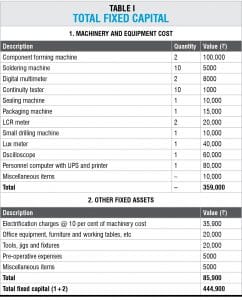

Equipment required

LED light manufacturing or assembly is a complex process. Machines need to be selected on the basis of the specific LED type that is being produced and the raw material being used. However, major machines include:

1. LED PCB assembly machine

2. LED lights assembly machine

3. High-speed LED mounting machine

4. LED chip SMD mounting machine

5. Candlelight assembly machine for LED

6. LED tubelight assembly machine

Other equipment that may be required:

1. Soldering machine

2. Sealing machine

3. Small drilling machine

4. Packaging machine

5. LCR meter

6. Digital multimeter

7. Continuity tester

8. Lux meter

9. Oscilloscope

Pollution control requirements

The following steps may help to control pollution wherever applicable:

1. Fumes and gases are released during hand soldering/wave soldering/dip soldering, which are harmful to people as well as the environment and end products. Alternative technologies may be used to phase-out the existing polluting technologies. Numerous new fluxes have been developed, which contain 2-10 per cent solids as opposed to the traditional 15-35 per cent solids.

2. CFCs, carbon tetrachloride and methyl chloroform are used for cleaning of printed circuit boards after assembly to remove flux residues left after soldering and various kinds of foams for packaging. Many alternative solvents could replace CFC-113 and methyl chloroform in electronics cleaning. Other chlorinated compounds such as trichloroethylene, per chloroethylene and methylene chloride have been used as effective cleaners in the electronics industry for many years. Other organic solvents such as ketenes and alcohols are effective in removing both solder fluxes and many polar contaminants.

LED light manufacturing business registration

The entrepreneur needs to obtain following registrations and licences from government authorities:

1. Company registration with ROC

2. Trade licence from municipal authority

3. Udyog Aadhaar MSME registration

4. BIS certification

5. Bureau of Energy Efficiency certification

6. NOC from Pollution Control Board

7. GST registration

However, specific licence and registration requirements will depend on the manufacturing process and the type of LED light that is being produced.

Business economics

Under Modified Special Incentive Package Scheme (M-SIPS), the Indian government provides a special incentive package to promote large-scale manufacturing in the electronic system design and manufacturing (ESDM) sector. This scheme was amended on August 3, 2015. Salient amendments to the scheme include:

1. The term of the scheme has been extended up to 27-07-2020.

2. The scope of the scheme has been extended to cover additional verticals.

3. The procedure for grant of approval has been simplified and streamlined.

Incentives are now available for investments made in a project within a period of 10 years from the date of application.

Land and building

Builtup area: 280sq.m (3000sq.ft) office

Store: 93sq.m (1000sq.ft)

Assembly and testing: 185sq.m (2000sq.ft)

Rent payable per month: ₹ 10,000

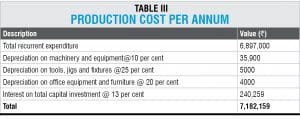

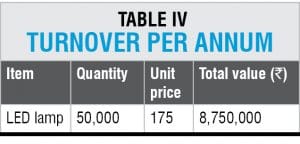

Financial analysis

Profit per annum (before taxes) = Turnover per annum–Production cost per annum= ₹1,567,841

Net profit ratio=(Profit per annum)×100/(Sales per annum)

Rate of return=(Profit per annum) ×100/(Total capital investment)

Breakeven point.

Breakeven point=(Fixed cost) ×100/(Fixed cost+Profit)