The quality of light is what drives the growth of the LED lighting market. Perfect colour uniformity and low glare are what customers need, and manufacturers must pair LED lighting with the proper optics to meet these requirements.

By Shruti Mishra

Optics is a crucial aspect of any LED luminaire because it helps in reducing glare, which is one of the most common problems associated with LEDs. Good optics involves mixing, shaping and focusing the light created by LED sources to the place it is required. Without well-designed optics, it is almost impossible to get the most efficient performance from an LED luminaire.

Most LED lighting systems use both primary and secondary optics. In general terms, primary optics is built into the LED itself, and serves to protect the light source and shape the output of the small diode. This usually takes the shape of a small dome on top of the LED source, which provides the basic beam shape to the fixture. However, the light from the primary optics is still too broad and lacks intensity over a distance. This is where secondary optics comes in, as it helps to converge the broad beam of light and magnify its intensity towards the target. In addition, good optics also enhances the colour uniformity and light distribution within the targeted area.

The most common type of secondary optics uses reflectors and lenses. Reflectors are easier to implement and are low cost, but are not capable of completely eliminating glare. This is because most of the light rays coming out of the LED source pass out of the luminaire without even touching the reflector, leading to a loss of lumen output and the creation of unwanted glare. Total internal reflection (TIR) optics or TIR lenses solve this problem by directing the light from the source’s centre to the reflector, which then sends this out in a controlled beam.

The design of the secondary optics involves an additional cover over the system, which provides some scope to modify the light. Engineers these days are making use of a variety of lens materials to optimise the light diffusion properties and to remove the glare associated with LEDs. Let’s take a look at some advanced lens materials and their usage.

Advances in lens materials

Glass LED lenses have long been used in the LED lighting industry for various aesthetic and functional purposes, in optical designs. It is the high light transmission and resistance to discolouration that made these LED lenses popular in the early days of LED lighting. But soon these lenses grew unpopular due to their fragile nature. While searching for mechanically high-performing materials, engineers developed thermoplastics, which have high impact ratings. These newly engineered plastic materials not only offered a strong platform to build on, but also helped in meeting new energy efficiency standards with custom solutions for specific applications. The two widely used plastic solutions for LEDs are polymethyl methacrylate (PMMA) and polycarbonate (PC).

The biggest advantage of these thermoplastics is the flexibility they offer lighting engineers, compared to the rigidity of glass lenses. It is difficult to declare a clear-cut winner between the two because both PC and PMMA are quite similar in pricing and optical properties. Their suitability entirely depends on the kind of application for which they are being used. For instance, mechanical properties have a lower priority when you are designing lenses for indoor usage. In such cases, PMMA will be a good choice, considering the price factor as well. On the other hand, if the luminaires need to be placed in harsh conditions or need fire resistance properties, polycarbonate will be a wise choice.

Market drivers

The falling prices of LED luminaires has increased their adoption rate exponentially. This has increased demand for the components used in LED optics. A ResearchAndMarkets report shows that the overall LED lighting market will grow at a CAGR of 8.92 per cent during the period 2018-2022. And as LEDs become more affordable and deliver higher energy efficiencies, the optics will also become more vital.

Industry experts think that the secondary optics segment will embrace high-end technologies in order to maintain the pace of rapidly falling costs, making the overall end product more consumer-friendly. They also believe that seeing the immense growth prospects in the secondary optics market, many new manufacturers will enter the segment pretty soon.

Products available in the market

| Model: Superlinea lens; Manufacturer: Khatod Optoelectronic |

Superlinea is the newest strip lens from Khatod. It is designed for mid-power LEDs assembled in a linear array. Superlinea lenses are made of optical grade PMMA, and offer many symmetrical and asymmetrical beam options. They deliver uniform luminance, homogeneous light flux and smooth light distribution. The special surface texture of these lenses enables enhanced glare control, making them a good choice in any application requiring a substantial reduction of glare, such as in halls and offices. homogeneous light flux and smooth light distribution. The special surface texture of these lenses enables enhanced glare control, making them a good choice in any application requiring a substantial reduction of glare, such as in halls and offices.

Key features

Contact: www.khatod.com |

| Model: Barbara-G2; Manufacturer: LEDiL Oy |

LEDiL’s new Barbara-G2 is compatible with HEKLA sockets and connectors, and comes with a bayonet-fastening mechanism for quick installations and replacements. Optimised  performance for the latest mid-sized COBs and compatibility with LEDiL’s RZ-sublens allows it to be used in applications like retail and stage lighting. It comes with full RGB and tunable white colour mixing. performance for the latest mid-sized COBs and compatibility with LEDiL’s RZ-sublens allows it to be used in applications like retail and stage lighting. It comes with full RGB and tunable white colour mixing.

Key features

Contact: www.ledil.com |

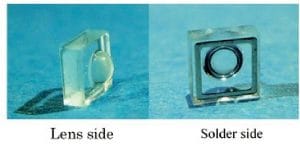

| Model: Quartz lens; Manufacturer: AGC Asahi Glass |

AGC has developed a quartz lens for deep ultraviolet LEDs. With this product, deep ultraviolet LED manufacturing processes can be significantly simplified and capital investments can be reduced. This product integrates the quartz used in the window glass with the lens, using AGC’s proprietary technology; so a transparent adhesive is not required. investments can be reduced. This product integrates the quartz used in the window glass with the lens, using AGC’s proprietary technology; so a transparent adhesive is not required.

Key features

Contact: www.agc.com |

| Model: Stradella; Manufacturer: LEDiL Oy |

The Stradella product family comprises dense lens arrays and tiny single lenses with high luminous performance. Beams are especially designed for street and high bay lighting, and modules are also available with a 50mm x 50mm footprint—similar to the Strada-2X2  optics. These lenses are optimised for mid-power applications, and are compatible with high-power and CSP LEDs. optics. These lenses are optimised for mid-power applications, and are compatible with high-power and CSP LEDs.

Key features

Contact: www.ledil.com |