Where there’s light, there’s heat. In spite of being a cold source of light, LEDs still produce heat as a by-product, which hampers their operations if not dissipated immediately. In this article, we look at some popular cooling techniques that are used to remove heat from LED-based lighting systems.

Where there’s light, there’s heat. In spite of being a cold source of light, LEDs still produce heat as a by-product, which hampers their operations if not dissipated immediately. In this article, we look at some popular cooling techniques that are used to remove heat from LED-based lighting systems.

By Shruti Mishra

Heat and improper thermal management are the greatest enemies of LED technology. From LED chips to related products such as LED bulbs, modules and fixtures, all have a major issue with higher temperatures. Prolonged heat can result in a significant drop in performance and even mechanical failures in LED systems. Many a time, this causes permanent lumen degradation in LEDs, even if the issue with high temperature is resolved. Therefore, an efficient heat removal mechanism is an important factor in ensuring that LED systems deliver the expected level of performance during their lifetime.

Heat transfer modes: Conventional light sources vs LED sources

Conventional light sources like fluorescent lamps dissipate the heat through the emission of infrared rays and convection, which is why they do not require any advanced thermal management solution to facilitate the process.

LED sources release heat through conduction, which requires additional understanding of how to efficiently carry waste heat out of LEDs in order to prevent performance degradation and system failure.

Classification of thermal management solutions for LEDs

Depending on their applications, LED cooling techniques are broadly divided into active solutions, passive solutions and thermal interface-based solutions. Let’s now delve a little deeper into the functionality of these three technologies.

Active cooling: Active cooling requires the inclusion of a sub-system that forces air out of the lighting system to keep it cool. This technology includes conventional electric motorised fans and diaphragm-based forced air cooling. The greatest advantage of using active cooling solutions is that they can result in remarkable size, weight and cost reductions in high power LEDs.

- Conventional fans: Electric motorised fans are the traditional active cooling solution that are not orientation-dependent. Therefore, this design allows for a much smaller and lighter LED light that can fit in smaller and enclosed fixtures without any issues. On the downside, these fans consume extra electricity. Also, multiple moving parts make the device a bit noisy, which may cause issues of reliability and performance degradation, over time.

Usage: The presence of a fan helps LEDs operate in higher ambient temperatures than passively cooled LEDs, which makes them more suitable for outdoor fixtures operating in a hot climate. - SynJet technology: To overcome the noise problem of cooling fans, the LED industry has adopted another active cooling method known as Synthetic Jet (SynJet) technology. In this method, a flexible diaphragm is used to perform the periodic suction of hot air, which is then ejected out of an opening. If used along with a heat-sink, the oscillating diaphragm expels the hot air over the fins of the sink to produce convection cooling.

Apart from the low audible noise, other advantages offered by SynJet technology include increased thermal efficiency, high reliability and low power consumption.

Usage: Since this technology is extremely customisable, it gives creative freedom to the design engineers. So, SynJet based LEDs are perfect for commercial and indoor applications.

Impact of inefficient thermal management on LEDs

- Decreases lifetime and reliability

- Lowers light output

- Yellowing of white LEDs with a rise in temperature

- Causes mechanical failures

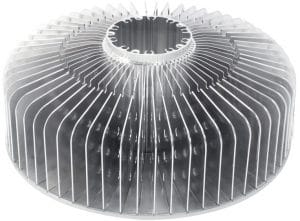

Passive cooling: This cooling method uses metal heat-sinks to draw heat out from LEDs. The heat-sink is a system that transfers heat from any solid material to a fluid medium like air or water. Since the operation of passive cooling solutions is orientation-dependent, LEDs that use these tend to be bulky and heavy. Being noiseless, this cooling method does not suffer performance degradation in the long run. Metal heat-sinks, heat pipe heat-sinks and ice heat-sinks are some of the passive cooling solutions actively used in high power LEDs.

Passive cooling is not good for LEDs that need to be in an enclosed fixture and such systems also cannot operate reliably in very hot climates.

Usage: This noise-free cooling solution is good for residential applications.

Buying tips for LED thermal management solutions:

- Opt for cooling solutions that provide high thermal conductivity with a low or controlled coefficient of thermal expansion (CTE).

- The cooling solution should operate efficiently even in very low power conditions.

- It should have a flexible and adaptable design.

- The cooling device must be capable of withstanding extensive vibrations.

- For outdoor applications, choose the option that offers full moisture protection.

- For indoor applications, pick noiseless SynJet or passive cooling solutions.

Thermal interface material (TIM) based solutions: TIMs are installed between heat generating units and heat-sink units to facilitate the heat transfer. In case of LEDs, a wide variety of TIMs including adhesives, pastes and rubber-like compounds are used to manage thermal issues. They are broadly divided into two parts: silicon-based TIMs and silicon-free TIMs.

- Silicon-based TIMs: This technology is widely used for outdoor LED fixtures installed in harsh climatic conditions. Silicon offers unmatchable thermal and optical stability. It is heat-resistant and can easily withstand high operating temperatures and the short wave exposures of today’s brighter LED lighting systems. Silicon absorbs vibration and with its low moisture absorption property, very effectively seals LED lighting systems that are placed outdoors.

One important development in silicon-based technology is liquid silicone rubber (LSR). Along with providing outstanding thermal protection, this lightweight material also helps LED manufacturers in replacing glass and thermoplastics with LSR, which offers excellent optical clarity, durability and design freedom. Optical LSR shows zero loss of transparency with age, or with exposure to heat and UV light.

The LED industry is inclined more towards LSR because it is completely scratch and crack resistant and therefore requires no additional maintenance. Also, in any traditional LED, designers have to use the lens and seal as two different parts but with LSR, they can combine the two into a single part which cuts down costs and overall inventory. - Silicon-free TIMs: The only reason why LED designers use this technology is that it eliminates the problem of silicon outgassing. These materials offer efficient thermal transfer, along with enhanced performance with thermal shock cycles and greater thermal protection in regions where temperature spikes can occur. These are available in various forms like paste, pads, grease, etc.

Usage: A TIM-based cooling solution is good for both indoor and outdoor LED applications. However, silicon-based TIMs are more suitable for LED streetlights and outdoor fixtures which operate under harsh climatic conditions.

Picking the right product

Selecting the right thermal management solutions for LEDs can be a daunting and time consuming process, as one has to choose a perfect solution from several forms of thermal management technologies available in the market. Before picking any cooling method, it is important to decide what type of cooling solution your LED system needs.

Padmanabha S., general manager, Electrolube, while discussing the new technology involved in thermal management for LEDs, says, “Whatever thermal management material is chosen, it must be able to offer efficient heat transfer under the range of conditions the unit may be exposed to. New technologies for thermal management include highly thermally conductive phase change materials which, due to the change in their physical state, can offer more stability over the lifetime of the product, particularly in environments of changing temperatures.” It is also advisable to choose a protective material with good thermal conductivity and moisture protection, combined with ease of processing, to ensure complete encapsulation of LED assemblies.

A few products available in the market

Model: TPM350, Manufacturer: Electrolube

TPM350 is one of Electrolube’s latest high-performance product innovation in the thermal interface material range. TPM350 has a thermal conductivity of 3.5W/m.K and becomes workable at approximately 50°C. At this ‘activation’ temperature, it changes state to become a lower viscosity material, minimising contact thermal resistance and improving thermal conductivity. Once it cools, it reverts back to its original state. The material’s advanced formulation ensures minimal contact thermal resistance.

Key features

Key features

- Colour: Gray

- Operating temperature range: -40°C to +125°C

- Phase change temperature: 50°C

- Specific gravity: 2.8 g/ml

- Thermal conductivity: 3.5W/mK

- Volume resistance: 3 x 1012 ohm-cm

- Contains solvent, excellent ‘wetability’

- RoHS-2 compliant

Contact: www.electrolube.in

Model: Igloo SR250HP-3, Manufacturer: GlacialTech

These lightweight aluminium heat-sinks are manufactured using a stamping process which allows them to achieve a good performance of 0.1125K/W thermal resistance. The heat pipe cooling system incorporated in the Igloo SR250HP-3 helps to efficiently cool the small surface area of CoB LEDs. The heat pipes situated in the base of the heat-sink efficiently absorb the heat generated by the LED, and carry it up and away from the thermally-sensitive LED module, finally dissipating and radiating the unwanted thermal energy into the surrounding air.

Key features

Key features

- Dimensions (Diameter x Height): 300mm x 115mm

- Weight: 2800g

- Material: AL1050+ three heat pipes

- Surface treatment: Anode

- Crafts: Stamping + bonding

- Thermal resistance: 0.1663°C/W

- Surface area: 1674579 mm²

- Reference design power: 200W

Contact: www.glaciallight.com

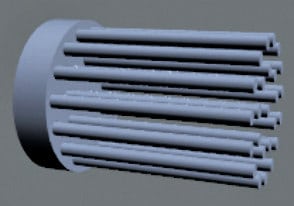

Model: LPF35A50 pin fin LED cooler, Manufacturer: MechaTronix

MechaTronix’s LED pin fin coolers are manufactured by cold forging from highly thermally conductive aluminium—AL1070. The combination of a cold forging process with the high thermal conductivity of 210W/mK leads to optimal cooling results of these high end LED coolers.

The major advantage of LED pin fin coolers is seen under tilted positioning of spot and track lights. Even on tilting the lighting fixture over an angle of more than 50 degrees, these pin fin LED heat-sinks keep performing optimally.

Key features

Key features

- Operating range: 300 to 1,000 lumens

- Thermal resistance: 7.41°C/W

- Dimensions (Diameter x Height): 35mm x 50mm

- Standard base thickness: 8mm

- Heat sink material: AL1070

- Cooling surface: 12436 mm²

Contact: www.mechatronix-asia.com

Model: LED heat-sink R150-170, Manufacturer: Aavid Thermalloy

This LED heat-sink has been custom designed for all major LED light engine manufacturers of industrial, high bay, low bay and outdoor LEDs. The high density die casting allows for near net shape LED thermal solutions using a high thermal conductive aluminum alloy. This heat-sink is designed using Aavid’s patented SynJet cooling technology that enables higher lumen output in a smaller, more efficient design.

Key features

Key features

- Maximum thermal performance: 0.64°C/W

- Maximum thermal performance with SynJet: 0.27°C/W

- Size: 150mm diameter, 170mm height

- Mounting size: 106mm diameter

- SynJet option: XFlow42

Contact: www.aavid.com

Model: 85W heat-sink, Manufacturer: Cree

Designed to be used with the 6000 lm and 8000 lm LMH2, Cree’s 85W heat-sink provides a simple and cost-effective method to improve the LMH2 thermal performance in various lighting applications. The 85W heat-sink is also compatible with Cree’s XLamp CXA3590 LED arrays.

Key features

Key features

- Thermal load: 85W

- Optimised for: 6000 lm and 8000 lm LMH2 LED module

- Product compatibility: CXA3590/CXB3590

- Attaches to the upper face of the LMH2 LED module with four screws

Contact: www.cree.com