Rishabh Instruments’ core competence is in manufacturing, design and development of T&M instruments and industrial control products. Having established a strong brand name across the globe, this firm is now set to enter the power electronics domain.

Rishabh Instruments’ core competence is in manufacturing, design and development of T&M instruments and industrial control products. Having established a strong brand name across the globe, this firm is now set to enter the power electronics domain.

By Baishakhi Dutta

Established in 1985, Rishabh has grown into one of the leaders in the Indian market. The company’s vision is to achieve growth through innovation and technological advancement in energy measurement, automation products and die casting. The company has a strong legacy of technology and an urge for innovation, and has been providing its customers with products of quality and reliability.

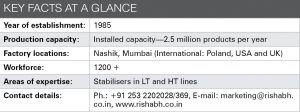

The company at a glance

Back in the day when computers ran on 8MB and India was yet to kick-off its foreign trade policies, Rishabh embarked as an analogue panel meter company. This was in 1985, in the small industrial town of Nashik. The initial days were a struggle but fortunately the firm’s German technology partners recognised Rishabh’s sound manufacturing capabilities and started buying its products, thus giving impetus to the fortunes of the company.

The young firm plunged into exporting analogue panel meters to companies that appreciated their quality. Rishabh consolidated as a company in the early 1990s. In the late 1990s, the electro-mechanical era started giving way to the digital age and in tune with this trend, Rishabh started manufacturing digital panel meters, transducers, and a range of test and measuring products like multimeters and insulation testers. This time, too, Rishabh collaborated with European partners for the right technology.

The Rishabh management team soon acquired expertise in buying, cost reduction and other manufacturing skills – sufficient to start the contract manufacturing of electrical instrumentation products for reputed companies in the West. Rishabh soon became a strong outsourcing partner to companies, who apart from the cost advantage, also appreciated their Indian counterpart’s investments in new technologies and in-house engineering prowess.

At Rishabh, we have believed in the spirit of “Make in India” for the last three decades. The very first products we manufactured were, in fact, for export to international customers. Our business ethos, since inception, has been to deliver consistently ‘best in class’ quality and ‘technology-centric’ solutions for the world, which we now see as getting further reinforced under the limelight that the ‘Make in India’ campaign provides to SME businesses like ours. The positive essence of the Make in India campaign will, no doubt, indirectly benefit Rishabh, like it would other Indian products in international markets.

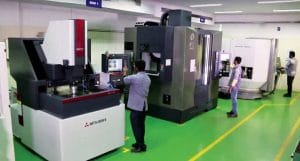

Manufacturing floor at a glance

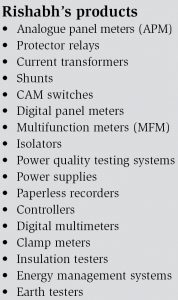

Rishabh has a unique product portfolio of industrial control products (ICP), comprising both analogue as well as digital T&M products.

To have better control over quality and to provide flexibility when addressing its customers’ needs, Rishabh Instruments has focused on creating end-to-end production infrastructure for its entire spectrum of ICP and TMI products. The company has set up an R&D centre where the product is conceptualised and designed, after which the required tools and moulds are manufactured in-house with the help of state-of-art machinery from renowned firms such as Charmilies and Makino for CNC wire cutting, spark erosion and vertical milling.

Component manufacturing from these moulds/tools is done in-house. For this, the company has invested heavily in world class moulding machines such as Arburg (Germany), Engel and L&T Demag, as well as press machines such as Bruderer (Switzerland), Hansel, etc.

The product manufacturing set-up consists of high end calibration equipment from Zera, Yokogawa, Calmat, Fluke Omicron and ELTEL, which enables the company to provide consistently accurate products to the market. In order to build reliability, the company has invested in an automated SMT set-up, which includes Fuji pick-and-place robotics systems and ERSA (Germany) 13-zone reflow ovens.

The product manufacturing set-up consists of high end calibration equipment from Zera, Yokogawa, Calmat, Fluke Omicron and ELTEL, which enables the company to provide consistently accurate products to the market. In order to build reliability, the company has invested in an automated SMT set-up, which includes Fuji pick-and-place robotics systems and ERSA (Germany) 13-zone reflow ovens.

Rishabh operates under tight process control on the assembly line to ensure reliable end products. For this, the manufacturing set-up is equipped with VISCON (Germany) AOI (optical imaging) machines for PCB quality checking, enabling the QA team to ensure high quality assemblies the first time itself.

All products are manufactured under close supervision and are tested on automated closed loop testing set-ups, which ensure defect-free products to the customer. Rishabh Instruments’ guiding philosophy is ‘Quality is built-in’. Its quality lab is equipped with state-of-art machines for inspection at the inward quality check stage, in-process phase and the final inspection stage.

Rapid eye profile projectors, type testing equipment such as vibration testers, climatic conditioning chambers, Brookhouse (Germany) magnetic property checking machines and different types of gauges are some of the equipment used. All the calibration equipment are calibrated in NABL accredited labs of Rishabh Instruments and comply with national and international standards.

A provider of end-to-end solutions

A provider of end-to-end solutions

Rishabh manufactures sub-assemblies and complete products in the electrical, electronic and electromechanical domains for its customers. The company’s end-to-end solutions range from the design and development stage to the manufacture of tooling, and from sourcing of components to BOM conversion and materials management.

Certifications

The company is ISO 9001:2008 certified. It has world-class facilities to test instruments as per IEC, DIN, IS and ANSI standards. The company’s products also have UL, CSA, CSE, GOST, and ASTA certifications. The QA lab is equipped with highly accurate calibration and testing equipment like Datron Wavetek, Fluke, Zera and Yokogawa for current and voltage standard calibration, vibration testing, an environment chamber for high voltage testing and an insulation tester. The quality management system of the firm is ISO 9001:2000 certified and has had this certification since April 1985.

Testing and calibration

Rishabh has consistently invested in end-to-end manufacturing infrastructure in order to control quality by minimising outsourcing. Every device produced at Rishabh comes with test certificates.

Rishabh’s testing and calibration laboratory, with NABL (National Accreditation Board for Testing and Calibration Laboratories) accreditation, is as per ISO/IEC 17025:2005 standards in the electro-technical field.

Take on ‘Make in India’

Take on ‘Make in India’

The company believes that the high pitched Make in India programme marketed across the globe has indeed resulted not only in better visibility for India as a manufacturing epicentre, but more importantly, enhanced ‘brand India’ worldwide. While the exact quantum of incremental manufacturing capacity getting created in India through this campaign (apart from additional employment opportunities being generated) can be measured only over the medium term, the immediate impact has been two-fold. The first is the impetus to entrepreneurial skills within India, and the second is the boost to exports of engineered and technology products and solutions.

Capabilities and strengths

Rishabh’s initiatives and approach have helped it build customer satisfaction in India and across the globe, and that is the biggest testimony of its quality standards. Rishabh has been among the largest manufacturers of analogue meters across the globe, a leading pioneer in touch-screen technology in MFMs and also a pioneer in introducing industrial grade multimeters. Some of its core strengths include:

- A solutions and applications-driven approach

- Ninety-five per cent of components manufactured in-house

- Complete product development and life cycle management

Quality parameters

Rishabh’s R&D facility, which is approved by the Department of Scientific and Industrial Research (DSIR), and its certification lab have set the tone for ‘best in class’ design, engineering and testing. The Rishabh team also leverages the expertise of its European subsidiary, Lumel, to understand requirements in the global arena and keep abreast of international quality demands. These insights are then incorporated into the new product development process.

Rishabh’s R&D centre supports customers in the following areas:

- Product development

- PCB design

- Firmware

- Mechanical design

- Mould design

- NABL testing lab

- Product life cycle support

The journey so far

The journey so far

Rishabh’s facilities in India and Poland, which are technologically on par with the evolving market, cater to its customers’ most stringent manufacturing needs. With over two decades of experience in manufacturing, sourcing and cost reduction, Rishabh’s vertically integrated manufacturing has been a logical alternative for many global companies. Being a manufacturer, Rishabh understands businesses better, stays on top of the latest technologies and has proven practices of effective supply chain management.

Expansion plans

Rishabh Instruments has enhanced its infrastructure for in-house moulding facilities with the addition of more high-end machines. Automated conveyor-based production facilities in CT manufacturing, including core manufacturing and online test set-ups, will enhance the scope of the manufacturing plant to give consistently reliable products.

A completely new production area is being developed for power electronics, which will be a milestone for the organisation. An already automated digital manufacturing set-up is being further expanded to include auto-insertion stations, inspection facilities, flying probe machines and closed loop automated high-end calibration set-ups.

Uncompromising standards for quality—not only for functional parameters but even for aesthetics—are being strengthened and heavy investments are being made in terms of in-house printing machinery. Overall Rishabh is expanding into new doamins such as power and power electronics and other new technology products.