Highly efficient, compact printers with the automatic stencil cleaning option are the latest trend in the market. These new stencil and screen printers have technical specifications that make them more precise, reliable and suitable for various applications in the electronics industry.

By Sneha Ambastha

ITW EAE’s MPM 100

ITW EAE’s latest solder paste printer, the MPM 100, was launched in August 2016 for the Asian markets. According to the company, the printer’s stencil cleaning system (which uses the standard wipers) comes with an improved ‘rapid clean’ feature that reduces the cleaning cycle time by 5 to 6 seconds. It allows users to add or retrofit innovative patented features to it, depending on their requirements. Owing to its technical specifications, the MPM 100 can be used in various applications that require high reliability.

Key features

Key features

- Can be configured for standalone single lane or back-to-back (BTB) dual lane

- Has a system accuracy of about 12.5µm@6, a Cpk of ≥ 2, with Six Sigma capability designed into the process and independently verified

- Supports faster processing speeds through its CAN control drive architecture

- CAN architecture also reduces the overall amount of wiring and the mean time to repair (MTTR)

- Comes with a patented single look-up/look-down digital camera for the vision system

Key specifications:

PCB size: 609.6mm x 508mm to 50.8mm x 50.8mm

Wet print accuracy: +/- 20microns @ Six Sigma, Cpk ≥2.0

Maximum print area (X x Y): 609.6mm x 508mm

Print speed: 0.635mm/s to 304.8mm/s

Stencil frame size: 737mm x 737mm (adapters available for smaller sizes)

Power requirements: 200V AC to 240V AC (±10%) single phase @ 50/60Hz, 15A

Weight: 797kg

Dimensions: 1589.4mm x 1394mm x 1195.4mm

USP: High-performance printing at high speed and accuracy

Contact details: ITW EAE; Minnesota, United States; http://www.itweae.com

Indian distributor: NMTronics India Pvt Ltd, 0120-4603500, [email protected], www.nmtronics.com/smt/

DEK’s NeoHorizon

The DEK NeoHorizon is a new and improved screen printer with a completely modular design. Its cycle time of 6.5s and accuracy of up to 15µm at 2Cmk (±Six Sigma) allows the printer to meet high speed, accuracy and efficiency standards. As per various electronics manufacturing application requirements, this machine can be used along with several additional options like conveyors, clamping systems, camera systems and sensors. However, the most important feature of the machine is its ability to work with the latest version of DEK’s ProFlow ATx printhead system, which the company claims is its successful printer platform.

Key features

Key features

- Comes with a highly robust cover for easy operations and maintenance of the machine

- Has a back-to-back configuration that supports the flexible, smart and future-proof dual-track solution

- Two such printers can operate independently even when installed back-to-back or can be installed on two separate lines at any point in time

- DEK ProFlow ATx stabilises and automates the process of stencil printing, thus reducing the paste costs

Key specifications:

Maximum print area (X x Y): 510mm x 508.5mm

Squeegee adjustment: Motorised with squeegee pressure feedback

User interface: Touchscreen, keyboard and trackball, DEK Instinctiv V9 software

Power requirements: 100V to 240V ±10%; single phase 50/60Hz

Weight: Approx. 690kg depending on the selected options

USP: Smart printer with modular design that can be customised for customer-specific or application-specific requirements

Contact details: ASM Assembly Systems, Singapore; www.dek.com

India: ASM Assembly Systems India Pvt Ltd, www.asm-smt.com

GKG’s KSP

KSP is a fully automatic screen printer from GKG with many built-in features and flexibility. Launched in December 2016, this printer has an optical camera system with a simultaneous look up/look down, uniform ring light, and a high-brightness coaxial light with brightness control. This feature allows the system to handle all fiducial marks with high precision and resolution. It has a stepper motor to drive the conveyor belt controlling the PCB’s soft stop position with precision. Its squeegee has been made from high intensity steel for rigidity and durability.

Key features

Key features

- Comes with a single stage automatic conveyor with an anti-static U-shaped belt

- Has an arch shaped, steel squeegee beam for balanced and stable squeegee movement

- Its two automatic wet/dry/vacuum stencil wipers enable users to select any combination of cleaning mode as required by the application

- Its capability to save the stencil’s position for each file reduces the model-changing time drastically

- Its pneumatically operated buttons allow easy adjustment of the X frame to suit the stencil size without the need for a stencil adaptor

Key specifications:

PCB size: 50mm x 50mm to 510 mm x 510mm

Frame size: 480mm x 500mm ~ 737mm x 737mm

Power requirements: AC220V, 0.49 megapascal (MPa), single-phase

Machine weight: 1200kg

Machine dimensions (WxDxH): 206mm x 684mm x 410mm

USP: Fully automatic printer for optimum price-performance ratio with inbuilt features and flexibility

Contact details: GKG Asia Pte Ltd; Singapore; http://www.gkgasia.com

India: Juki India Pvt Ltd, 022 -42291160 / 61 / 62; [email protected], http://jukiindia.com/smt

Hanwha Techwin’s SP2-C

Launched in January 2017, the SP2-C is an upgraded version of the SP1-C. It comes with more stable hardware and software functions for flexible operations. The machine has a compact design, delivers high performance and enables high-speed production since two printers can be connected back-to-back for dual operation. It can be controlled by a specially designed mobile application. Apart from that, it offers high productivity as well as Six Sigma level high-quality printing. The SP2-C also supports high-speed mixed production.

Key features

Key features

Comes with a print defect detection system that consists of a mask-opening inspection function and a PCB temperature measurement feature for defect-free operation

Its print feedback system automatically inspects and cleans the mask openings, resulting in improved print quality

Minimises the consumption of solder paste by the automated supply of solder

Comes with a blower fan that creates a vacuum below the PCBs during the printing of micro components (like 0402/03015, etc) for improved lead dropping efficiency

Its height sensor allows automatic levelling of the printer height to the initial setting

Key specifications:

PCB size: 50mm x 50mm to 330mm x 250mm

Wet print accuracy: ±25μm@μ+6σ

Print cycle time: 5s

Stencil size:

- 550mm x 650mm to 736mm x 736mm

- 650mm x 550mm to 736mm x 736mm

Printing accuracy: ±12.5μm@μ+6σ

Power requirements:

- 100V, 110V, 120V, 200V, 220V, 240V (±5%) single phase

- Max. 4.5kVA, 50/60Hz

Weight: 1150kg

Dimensions: 1376mm x 1200mm x 1904mm

USP: Compact high-performance screen printer

Contact details: Hanwha Techwin Co. Ltd; Gyeonggi-do, Korea; http://smt.hanwhatechwin.com

India: Samsung C&T India Pvt Ltd, www.samsungcnt.com

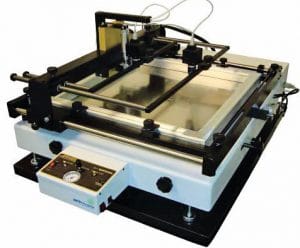

DDM Novastar’s SPR-45VA

The recently launched SPR-45V is a stencil printer with SMTrue vision assistance that allows high magnification (about 10 times) of components for precise alignment. It has an optional double nesting kit that quickly changes boards and the stencilling of single- and double-sided PCBs. The company claims the printer offers accurate stencil-to-board alignment. All these features make the SPR-45VA economical for various applications such as prototyping, short to medium runs and high mix production environments, as well as for printing chip-scale packages (CSPs), micro ball grid array (microBGAs) and ultra-fine quad flat packages (QFPs).

Key features

Key features

- Comes with a pneumatically adjustable, power sweep squeegee that can print with either single or dual strokes

- Has a power frame lift that enables high volume production

- Its dual squeegee holder has an independent print force adjustment feature for the clean and convenient application of solder paste

- Comes with a quick-change, spring loaded, double-sided PCB testing kit option for changing boards, and printing both single and double-sided PCB boards

- Has fine X, Y, and Theta adjustment settings for exact and repeatable alignment of stencil to board prior to printing.

Key specifications:

Maximum print area (X x Y): 406mm x 457mm

Stencil frame size: 584mm x 584mm

Power requirements: 120V AC, 50/60Hz, 2A (220V – 240V AC available)

Weight: 68kg

Dimensions: 406mm x 762mm x 889mm

USP: Ultra-fast stencil printer with precise alignment of components down to 12 mil pitch

Contact details: DDM Novastar Inc; Pennsylvania, United States; www.ddmnovastar.com

GKG’s GL Plus

GL Plus is an all-new, fully automatic stencil screen printer. Just like other SMT equipment from Juki, this printer has also been designed to meet the requirement for the ‘lowest cost of ownership’, and has been developed to meet the individual demands of customers. With just a 2-minute product changeover time and 10 minutes required for a new product set-up, the GL Plus is capable of reaching a process alignment of 2Cpk @ ±25 microns Six Sigma. This makes the machine precise, fast and flexible with continuous power improvements.

Key features

Key features

- Its two-way automatic wet/dry/vacuum stencil wiper allows users to select any option

- Its pneumatically operated buttons allow easy adjustment of frame size, based on the stencil size; hence, there is no requirement for a stencil adaptor

- Its automatic pressure check system ensures the adoption of optimum squeegee pressure

- Its 2D paste inspection feature ensures print quality by inspecting the solder paste deposition in critical locations like QFP and BGA

- Has an optional external temperature control unit to maintain the optimum operating temperature on the stencil in order to enhance the solder paste printing quality

Key specifications:

PCB size: Max. 510mm x 510mm

Squeegee type: Metal: 280mm, 350mm, 520mm (Std.)

Squeegee speed: 10mm/sec~200mm/sec

Stencil frame size: Adjustable, 480mm x 500mm to 737mm x 737mm

Power requirements: 220V AC, ±10%, 50/60Hz, single phase

Machine weight: 1200kg approximately

Machine dimensions (excluding signal lamp): 1240mm x 1560mm x 1491mm

USP: High value stencil screen printing solution

Contact details: GKG Asia Pte Ltd; Singapore; http://www.gkgasia.com

India: Juki India Pvt Ltd, 022 -42291160/61/62; [email protected], http://jukiindia.com/smt