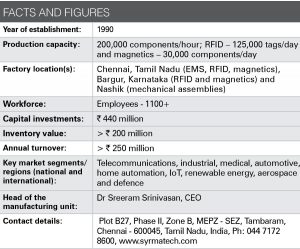

Based in San Jose, California and Chennai, India, Syrma Technology is part of the Tandon Group, with a 38-year legacy of electronics manufacturing. The company specialises in custom engineering design services and high-mix, flexible-volume manufacturing for global OEMs.

Based in San Jose, California and Chennai, India, Syrma Technology is part of the Tandon Group, with a 38-year legacy of electronics manufacturing. The company specialises in custom engineering design services and high-mix, flexible-volume manufacturing for global OEMs.

By Baishakhi Dutta

Manufacturing floor at a glance

Syrma Technology has extensive experience meeting global OEM specifications for numerous specialised electronic products, including custom and ‘built to print’ PCB assemblies, board builds, box builds for a wide range of industrial, medical and telecom applications, RFID tags, magnetics, disk drives, memory modules, power supplies/adapters, DC motors, fibre optic assemblies and a wide range of other specialised components.

Machines used at the facility: At Syrma, a typical state-of-art manufacturing SMT line (across India it has two SMT and two through-hole lines) consists of the following equipment:

- Screen printer

- Pick-and-place machine

- Reflow oven

- TH assembly line

- Auto wave soldering machine

- Automated depaneliser – V cut

- Routing machine

- Automated conformal coating machine

- Dedicated product assembly line

- Inspection equipment like AOI (automated optical inspection) and 2D X ray machines and 40X digital microscope

- Video measuring machine

- Other equipment – PCB baking oven, vacuum sealing machine and reflow profile kit

- Capable of handling different board types – rigid, flexible, ceramic substrate

- Multilayer PCBs

- Fine pitch placement up to 12 mil

- Component range – 0201 to BGA and micro BGA and CSP up to 55mm²

- 30 micron placement accuracy with 3 sigma capability

- Board size – 500mm x 450mm

- Capable of handling package on package (POP), TH components in SMT through the pin-in-paste method

- Electromechanical capabilities – sheet metal/stamped parts, casting/machining and surface treatment

Products manufactured

- EMS – printed circuit board assemblies with product build capabilities

- RFID – standard and customised active and passive tags, inlays in different form factors, multi-protocol RFID readers

- Memory – memory modules, customised high-capacity USB flash drives

- Magnetics – high-performance magnetic coils and transformers

Areas of expertise

- Collaborative design engineering services

- A partner of choice for transforming ideas and concepts into reliable products

- High-mix, flexible-volume precision manufacturing

- Complete product build capabilities with plastics, metals and casting enclosures

- Product life cycle management with re-engineering and BOM optimisation capabilities

A focus on quality

Syrma Technology places great emphasis on quality assurance among its suppliers. There are regular supplier audits on various parameters for performance evaluation. Other practices include process quality assurance, qualification of new builds, outgoing quality assurance, customer specific audits, reliability testing – predefined reliability and safety tests for incoming and outgoing parts, system quality assurance – quality system audits, and documentation control and traceability information management systems.

Testing labs

The company uses profile projectors, LCR meters, CROs, AC chromo sources, DC power sources, multiplexers, FCTs, manufacturing defect analysers (MDA), etc. It has a technical team that develops customised functional testers. Syrma also uses reliability test equipment like environment chambers and BUMP testers. It has a dedicated lab for box build testing with a coordinate measuring machine (CMM) and virtual machine manager (VMM). It is also assisting in installing an XRF (X-ray flourescence) analyser at its major supplier for the analysis of plating parameters.

Managing the supply chain for components

According to company sources, Syrma maintains a well positioned global supply chain ecosystem through 120+ vendors across 12+ countries. A combination of OEMs and distributors help the company to ensure smooth supply chain management.

Selecting the right vendors

The company selects its vendors based on certain parameters such as support for service and spares, equipment reliability and the capability to upgrade to the latest technology.

Skills upgradation

In order to continually update and improve employees’ skills, Syrma follows certain skills upgradation policies such as:

- Induction and orientation training for newcomers

- Structured training offered to achieve specific individual, departmental and organisational objectives

- Technical training programmes for operators at its in-house skills development centre with internal faculty

- Real-time training at other world class manufacturing facilities

- Management development programmes for senior management team

- Sponsorships for external conferences and seminars

Certifications

Syrma has received the following certifications so far:

- ISO14001-2004

- ISO9001-2008

- ISO13485-2003

- TS16949-2009

- OHSAS 18001-2007

Measures taken for labour management

- The company’s safety, health and environment (SHE) team routinely reviews, improves and ensures a safe and healthy working environment

- A cross-functional team (CFT) comprising members from all verticals/departments ensures smooth and hassle-free work processes

- The corporate social responsibility (CSR) team supports and helps Syrma employees as well as others on humanitarian grounds

- A ‘Prevention of sexual harassment’ committee ensures a safe working place for female employees

- A canteen committee provides quality and hygienic food

- The emergency preparedness team responds to any emergency situations, natural disasters or an interruption of business operations

- The first aid team was set up to ensure emergency readiness

- A core team has been formed across all functions to prepare future successors and work together for the smooth transition of business activities

Talent management

- The company’s ‘grow from within’ scheme provides employees with opportunities to pursue their career goals and reach new heights within the organisation

- A graduate engineer trainee programme is conducted

- Outstanding contributors are recognised and rewarded

- Fun activities and skills competitions are conducted to enhance interpersonal skills

Recent investments

Apart from investing continuously every year, in July 2017, Syrma invested around ₹ 98 million in new machinery.

Incentives from the government

Syrma has applied for certain incentives from the state and Central governments in order to enhance its manufacturing capabilities. These are:

- Board of Apprenticeship Training (BOAT) subsidy – The application process is still ongoing

- Merchandise Exports from India Scheme (MEIS) – The application process continues

- Modified Special Incentive Package Scheme (MSIPS)—Approved, though the company is yet to receive the incentive

Expansion plans and possible challenges

The company has already planned to add a new production line at its EMS plant in Chennai. Apart from that, Syrma also plans to set up another EMS plant at the domestic tariff area either close to Chennai or in the National Capital Region. However, the key challenge that the company faces is in acquiring competent technical manpower.

Steps taken for a greener environment

In order to be environmentally responsible, Syrma has converted all the lights at its shop floor to LED lighting in addition to several other energy saving initiatives. In order to reduce wastage, the company has started recycling solder dross. As part of its OHSAS 18001 and ISO14001 certifications, Syrma uses authorised and safe methods of handling its e-waste and bio-waste. Syrma has been certified as a Green Rated supplier by a major European MNC after a rigorous Sustainability Audit.