The careful selection of capacitors based on a proper knowledge of their specifications is essential to ensure that they do not compromise the life of LED products.

The careful selection of capacitors based on a proper knowledge of their specifications is essential to ensure that they do not compromise the life of LED products.

By Shruti Mishra

LED lighting systems have improved immensely in terms of quality and efficiency, over the years. In order to enhance the aesthetic appeal in architectural spaces, LED luminaires these days are becoming more sleek, elegant and sophisticated. But one thing that has remained unchanged in this evolution of LEDs is their basic design, which consists of the LED chip, ICs and capacitors.

Since LEDs are known for their robustness and longer operating life, using just about any circuit or component with them can negatively impact their reliability. To achieve the maximum luminous output, LED manufacturers [To find the complete list of LED Light manufacturers in India click here] tend to use high efficiency LED drivers, which are designed with long-life capacitors. Among all the electronic components used in an LED driver, capacitors have the highest failure rates as they are more vulnerable to electrical, mechanical or environmental overstress, though they are extremely reliable when used correctly.

Capacitors are generally used in LED drivers for smoothening and reducing the ripple coming from the power supply. Selecting the right capacitors for LED lighting systems helps in avoiding flickering, eliminates excessive heat, and ensures longevity of the LED lights.

Points to consider before buying a capacitor

In order to pick a suitable capacitor, one important factor that should be kept in mind is its voltage rating. Each capacitor comes with a maximum voltage rating and therefore, while selecting a capacitor for LEDs, do factor the amount of voltage applied across the capacitor. The working voltage of all capacitors depends entirely on the type of dielectric material being used and its thickness.

What happens if you choose the wrong capacitor?

Selecting the wrong capacitor can adversely affect any LED circuit because of the cracks formed in the dielectric material of these capacitors. This phenomenon is known as dielectric breakdown and is one of the main causes of failure in capacitors. If the applied voltage across the capacitor becomes too high, the dielectric material will break down, forming an arcing between the capacitor plates, resulting in a short circuit.

Types of capacitors that are used in the LED industry

Electrolytic capacitors

These capacitors always remain a popular choice due to their low cost. They are a type of polarised capacitor that smooth the voltage going to the LED driver as well as the current flowing through the LEDs, so that these do not flicker at high speed.

The most common type of electrolytic capacitor is the aluminium capacitor. It offers greater capacitance per volume than any other type.

[Click here to find the Indian distributors of Electrolytic capacitors]

Limitations: Electrolytic capacitors are very temperature sensitive. The electrolyte present inside them is in the form of a gel, which evaporates gradually due to the heat generated during operations. Higher operating temperatures speed up evaporation and hence shorten the life of the capacitor.

Ceramic capacitors: These fall under the category of non-polarised capacitors and are widely used for sleeker LED designs. Multiple ceramic layers are arranged and compressed in the form of a block that reduces the size of the circuit boards. These capacitors show stable performance at high temperatures with improved humidity resistance.

[Looking for the distributors of Ceramic capacitors in India? Click here to find them]

Limitations: Ceramic capacitors operating with a pulse width modulation (PWM) dimmer circuit can cause acoustic noise and light flickering due to piezoelectric effects within the ceramic material. Another potential obstacle is that a ceramic capacitor cracks during over-voltage, which may cause open or short circuits. Also, these capacitors are not very flexible, which makes them more susceptible to mechanical stress.

Film capacitors: These are another type of non-polarised capacitors that contain an insulating plastic film as the dielectric. LED manufacturers prefer film capacitors over other varieties because they have the unique ability to heal themselves after electrical breakdown. They have excellent high-frequency and temperature characteristics, generally far better than those of ceramic capacitors.

Another reason for their popularity in the LED industry is that they are highly compatible with the latest LED assembly methods. The key advantages of film capacitors compared to the ceramic, aluminium electrolytic and tantalum capacitors are high reliability, extreme pulse currents, tight tolerances, low dielectric absorption and small capacitance change, regardless of the applied voltage.

[Click here to find the distributors of Film capacitors in India]

Limitations: First, their voltage performance deteriorates at high temperature. Second, these capacitors are not good for outdoor lighting purposes as they cannot withstand a humid environment and thereby show degradation in insulation resistance.

Third, they have a low dielectric constant, which means that they tend to be large relative to their capacitance and compared to other popular ceramic and aluminium electrolytic capacitors.

A few products available in the market

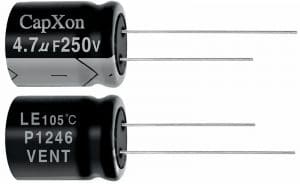

Model: LE series, Manufacturer: CapXon

CapXon has introduced the LE series of electrolytic capacitors, which provide high reliability and ultra-long life in LED lighting applications. Available in the UK from Components Bureau, the products operate over an extended temperature range of -40˚C to +105˚C, making them suitable for LED drivers that power outdoor lighting applications. This series offers a longer life than the FL series used in electronic lighting ballasts and energy saving luminaires.

Key features

Key features

- Operating temperature range: -40°C to +105°C

- Rated voltage range: 160V ~ 450V DC

- Rated capacitance range: 1 to 68μF

- Capacitance tolerance: ±20 per cent (120Hz,+20°C)

Contact: www.capxon-europe.com

Model: PG – LL9, Manufacturer: Alcon Electronics

Alcon manufactures a wide range of screw terminal aluminium electrolytic capacitors with a voltage rating of 50V to 500V DC. Following modern manufacturing methodologies and using the latest equipment ensures good quality and a wide range of capacitance ratings.

Key features

Key features

- Voltage range: 315V to 450V DC

- Can size: 50ϕ x 80mm to 90ϕ x 220mm

- Operating temperature range: -40°C to + 85°C

- Capacitance: 1000 MFD to 20000 MFD

- Tolerance ± 20 per cent

Contact: www.alconelectronics.com

Model: Polypropylene film capacitor, Manufacturer: Neotroniks Pvt Ltd

These types of capacitors use polyester as a dielectric material. They are ideal for light duty pulse, logic and timing circuits and LED lighting applications. They are also used in high frequency circuits and electronic ballasts.

Key features

Key features

- Tolerance: 20, 10 and 5 per cent

- Dissipation factor <= 0.001 at 1KHz at 25º C (Typical value: 0.004)

- Test voltage: 2.5 x Vr for 2 sec

- Max. pulse rise: 1000 V/usec

- Temperature range: -25º C to + 85º C

- Insulation resistance: >= 50 G for C <=0.33uF at 25º C

Contact: www.elciarcapacitors.com

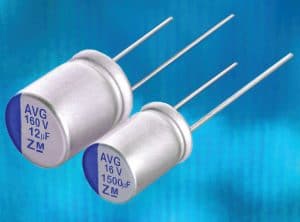

Model: AVG, Manufacturer: Illinois Capacitor

Illinois Capacitor’s aluminium polymer capacitors offer the very-low equivalent series resistance (ESR) benefits of polymer with higher maximum operating temperature and voltage ratings. Because of their low ESR, one aluminium polymer capacitor can replace up to three aluminium electrolytic capacitors. Compared to most other polymer capacitors, sources at Illinois Capacitor claim that it has products rated at a higher temperature (up to 125°C), up to 160 WVDC and greater CV (Capacity x Voltage) values. The products are very stable with regard to temperature and have good high-frequency performance. Apart from LED lighting, these capacitors are also used in telecommunication and power units.

Key features

Key features

- Operating temperature range: -55°C to +125°C

- Capacitance tolerance: +20 per cent at 120Hz, 20°C

- Dissipation factor: 120Hz, 20°C: 12 per cent maximum

- Load life: 2000 hours (1500 hours for WVDC>35V) at 125°C with rated WVDC applied

Contact: www.illinoiscapacitor.com

Model: Radial electrolytic capacitor, Manufacturer: Shanghai Yongming Electronic Co. Ltd

This aluminium electrolytic capacitor from Shanghai Yongming Electronic Co. Ltd is designed for highly advanced power supplies and other electronic devices. These capacitors are used in advanced power supplies, power sockets, road lamps, LED power devices, LED drivers, LED lamps, LED lighting, power meters and energy meters.

Key features

Key features

- Operating temperature range : ≤100V DC: -55° C ~ +105° C; 160V ~ 500V DC:-40° C ~ +105° C;

- Voltage range: 6.3V ~ 500V DC;

- Capacitance range: 0.47uF ~ 4,700uF

- Capacitance tolerance: ±20 per cent

- Ripple current: High (≈15mA/W)

Contact: www.sh-ymin.com

[Click here to find the distributors of all types of capacitors in India]